Aluminum Composite Panel & Aluminum Sheet Curtain Walling Deshion Products Overseas Installation

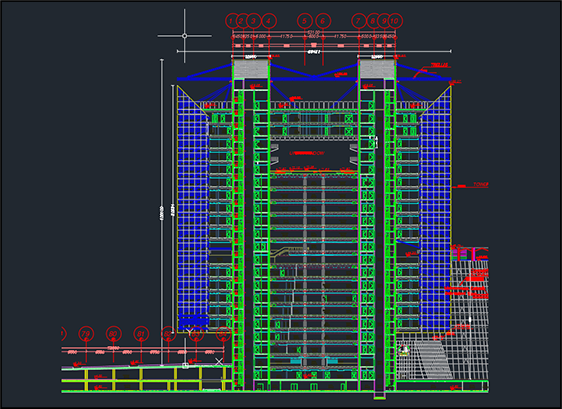

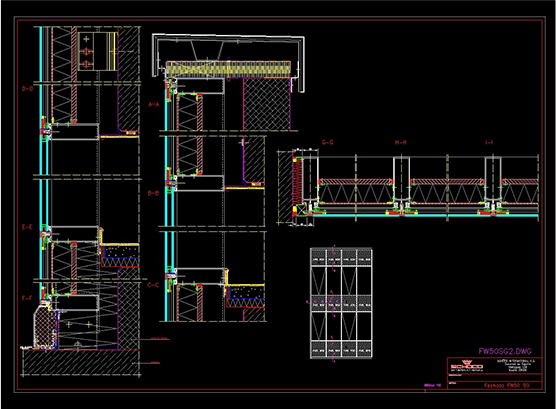

Full glass curtain wall structure

Aluminium panel facade is made by high strength aluminium alloy. The thickness are 1.5mm 2 .0mm 2.5mm 3.0mm. maximum width is within 1900mm, maximum length is within 6000 mm, model is 3003 (or 1100) H24. The panel is mainly composed of veneer panel, reinforcing rib and corner brace. Corner is not only made by punched and bend panel, but also made from small panel. Reinforced ribs is connected with welding screw and make them become firm whole, it enhance strength and rigidity of aluminium single plate, and also ensure the smoothness, wind-resistance and anti seismic ability of aluminium panel in long-term using. If you need to make it with sound insulation, heat preservation, you can install sound insulation and heat preservation materials inside the aluminium panel.

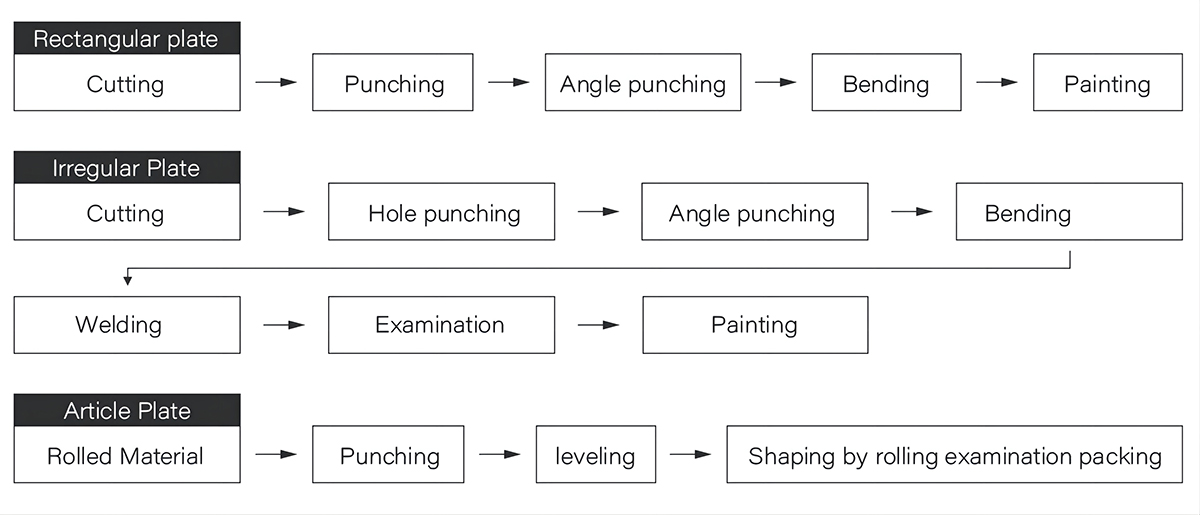

Sheet metal production process

Spraying process

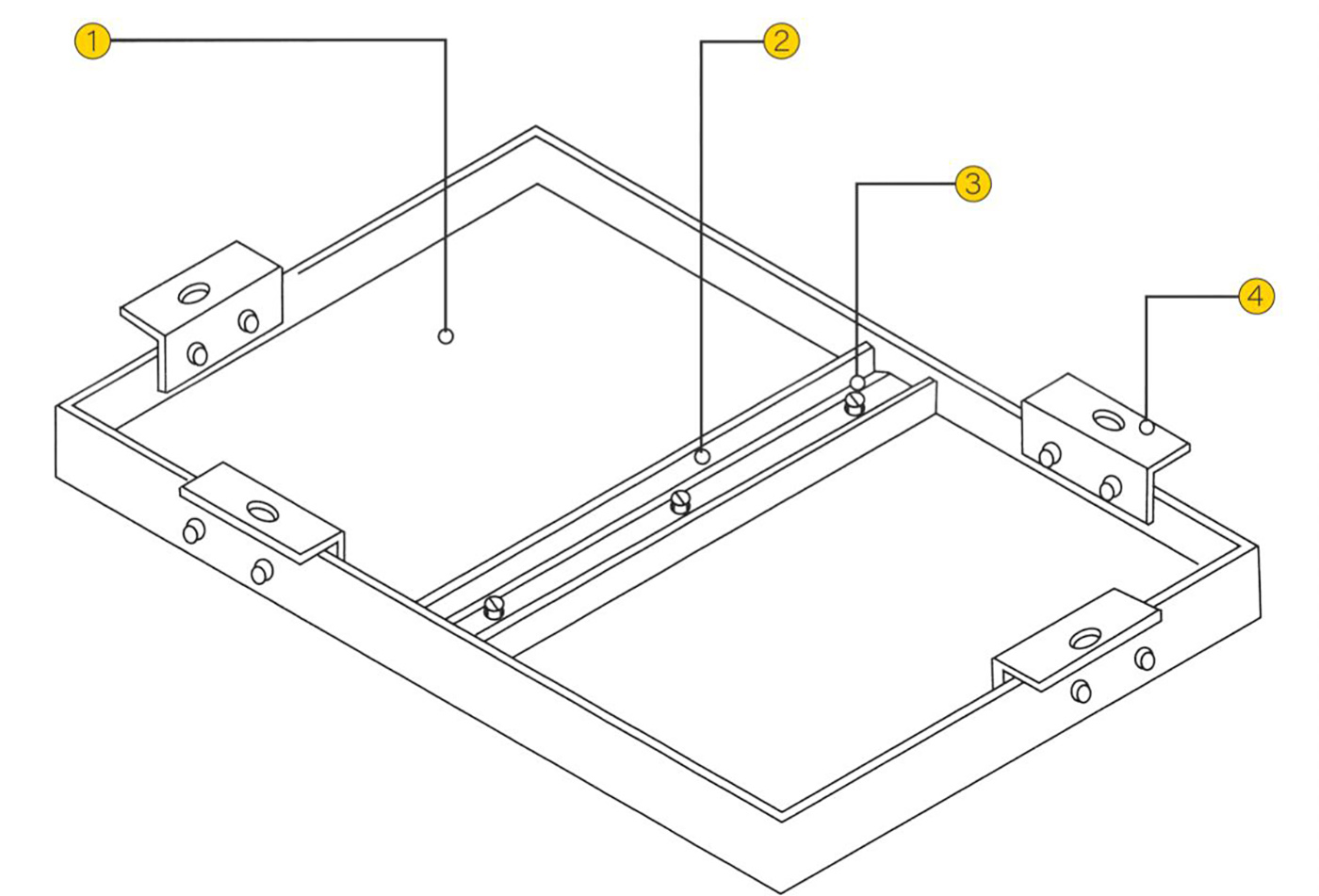

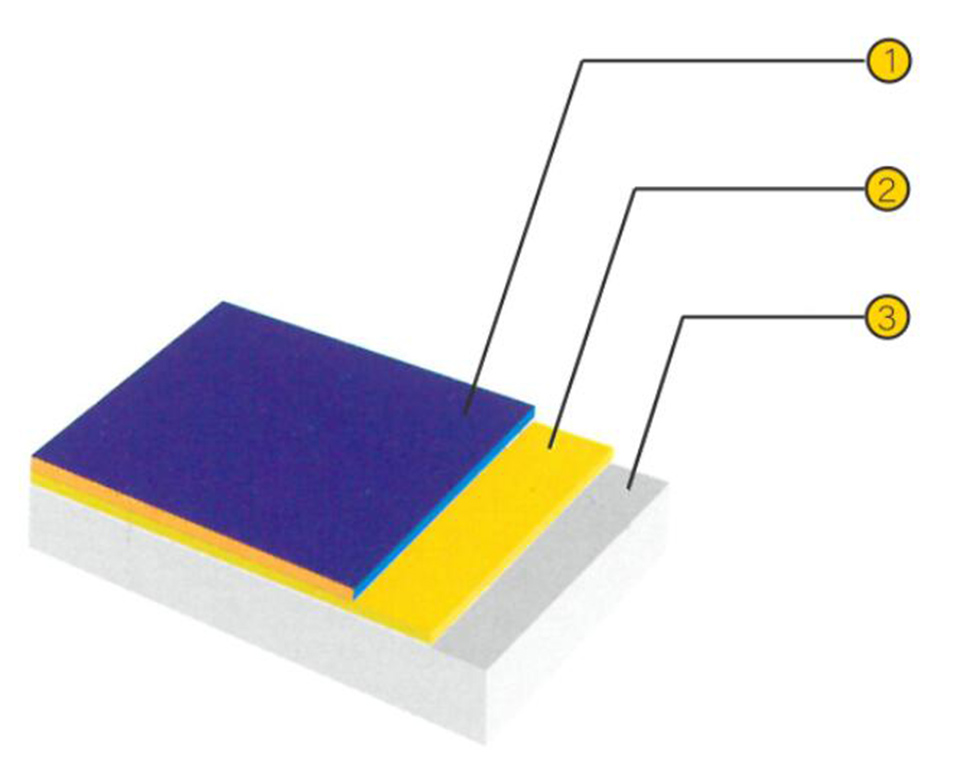

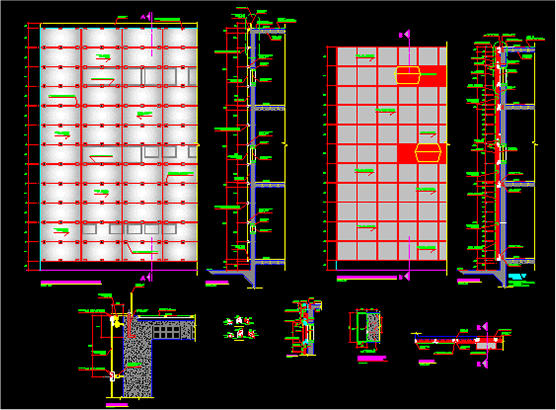

Mono-layer Aluminum Alloy Curtain Wall Plate Component Fig

1.Mono-layer Aluminum Alloy Curtain Wall Plate

2.Aluminum Alloy Stiffening Rib

3.Aluminum Nature Nail

4.Alumiuum Alloy Triangular Support

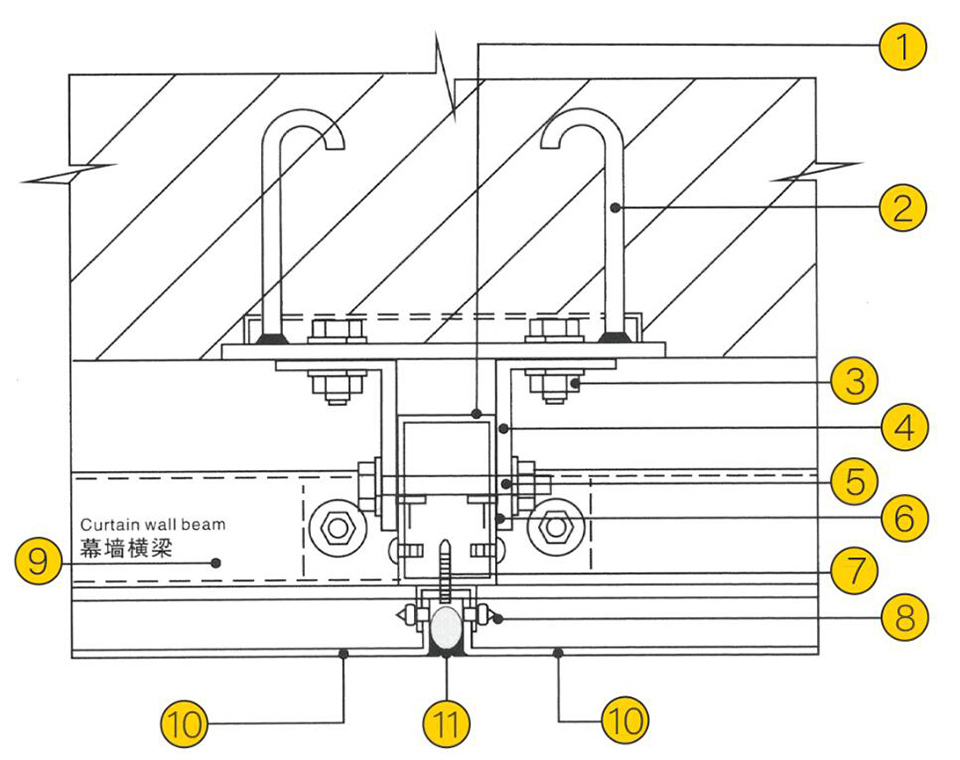

Aluminum curtain Wall veneer and phase diagram of the node

1.3mm thick curtain wall vertical beam

2.Curtain Wall applies zinc plated imbeddde parts

3.M12X35 stianless steel boltas

4.6mm thick zinc plaede steel angle brackdt

5.M12X100 stianless steel boltas

6.PVC cushion

7M4X16 stainless steel tapping bolts

8.Φ 5 aluminum rivet

9.Curtain wall beam

10.Aluminum Veneer

11.PE foaming filling material weather resistant sealant

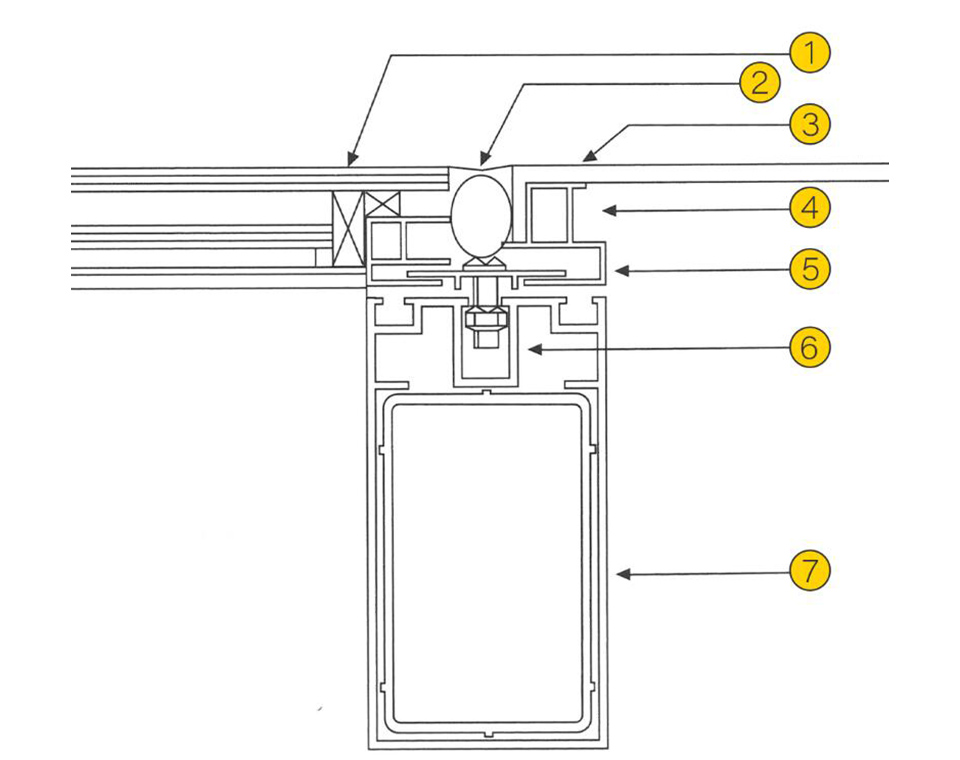

Aluminum and glass curtain wall veneer phase diagram of the node

1.Empoty centre glass

2.Durable sealanrts

3.3mm thick curtain wall vertical beam

4.Deoutu frame with aluminm planking

5.Code of pressure

6.M12X100 stianless steel boltas

7.Main standing post

Surface treatment of aluminum plate

The surface of curtain wall aluminum veneer is generally treated by fluorocarbon spraying after cleaned and chromated. Fluorocarbon coatings are divided into primers, top coats and varnishes, the main component is polyethylene resin (KYNAR500). It divided into two painted, three painted and four painted. Fluorocarbon coatings provide excellent corrosion resistance and weather resistance, it can resist acid rain, salt fog and various air pollutants, etc., excellent cold and heat resistance, can resist strong ultraviolet radiation and keep not faded for a long time. The surface is made of high-quality chlorofluorocarbon from PPG, DNT, AKZ0, NIPPON and other world-famous fluorocarbon coating manufacturers, a wide range of color choices, customers directly choose color from factory color chart or provided sample.

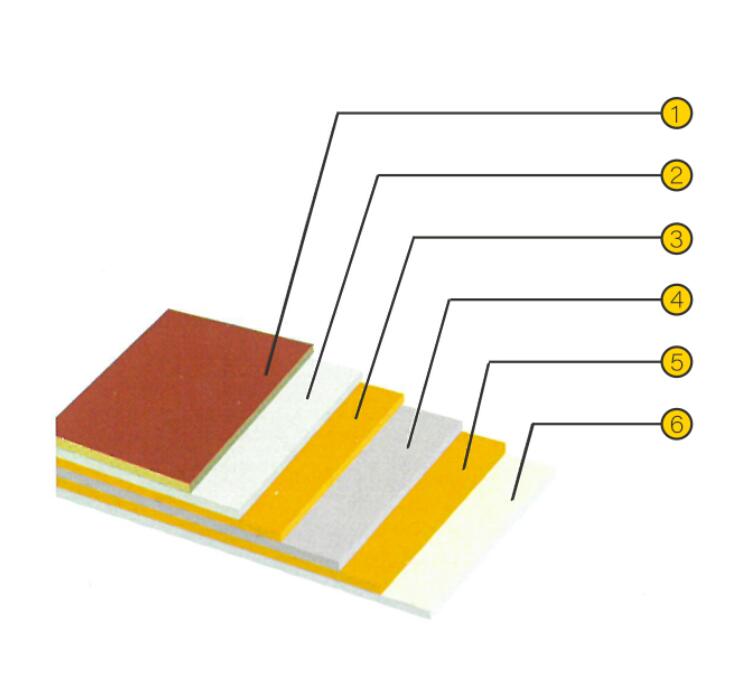

Roll paint

1.Surface layer paint

2.Primer

3.Chromium panel pretreatmernt layer

4.Aluminum plank layer

5.Chromium panel pretreatmernt layer

6.Primer

Roller coating plate is aluminum plate base material surface after degreasing and chemical processing, dry curing. Roller coating plate is the same as substrate materials and filmed panel. By high-performance roller coating processing technology, it can effectively control precision, smoothness, successfully eliminate the bump and wrinkles, and makes the decoration color uniform fine, soft and bright.

According to different coating and roller coating method, the roller coating plate also has certain difference on quality. The surface film thickness of roller coating panel is thinner than filmed panel, only 0.04 mm, so the normal roller coating board is 0.1 thinner than the same specifications of filmed panel. It’s not easy to produce color difference compared with filmed panel. The reflection of roller coating is very soft, easy to clean, and not easy to scratch discoloration, but the price is high.

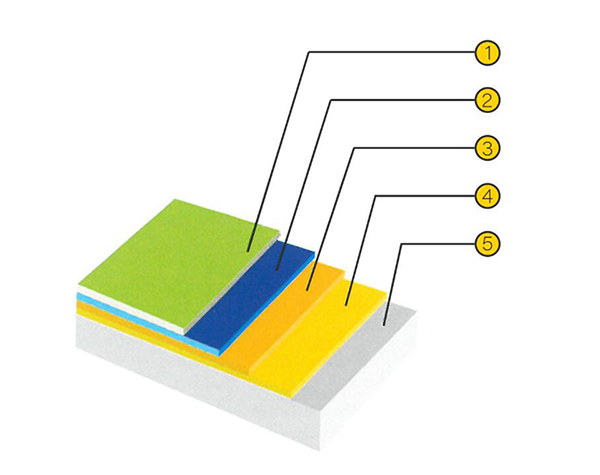

Roll paint

1.Varnish

2.Color surface layer paint

3.Primer

4.Chromium panel pretreatmernt layer

5.Aluminum alloy panel

The fluorocarbon resin PVDF used on the product is polyethylene pyrihadenone, which replaces part of the hydrogen atoms in the aliphatic carbon hydrogen molecular structure with fluorine atoms.

(Polyviny | Pyrrolidone) has the most negative charge of fluorine (F) thick and carbon (C) a fluorine carbon bonding force between the atoms is higher than 1054 kcal/mol, this means at least 105.4kcol/mol of energy is required to break the fluoro-carbon bond. The binding distance between fluorine and carbon is 1.36A, which is more than that between carbon. The binding distance is even shorter than 1.54A. Because of the stereoscopic hindrance of fluorine atoms, the structure is so tight that it is difficult to break the fluoro-carbon bond. HYLAR5000 is a trademark of PVDF resin registered by AUSMONT, USA. KYNARSDO is a registered trademark of PVDF resin by Atochem Norly Americo.

Powder spray

1.Powder layer

2.Chromium panel pretreatmernt layer

3.Aluminum alloy panel

Powder spraying means use powder spraying equipment (electrostatic spray machine) to spray the powder coating to the surface of the workpiece, under the action of static electricity, the powder will be evenly absorbed in the workpiece surface and forming a powdery coating. Powder coating shows different effects (different kinds of powder coating effects), after high temperature baking, leveling and curing. Powder spraying is superior to spray painting in mechanical strength, adhesion, corrosion resistance, aging resistance and other aspects, and the cost is also under spray paint.

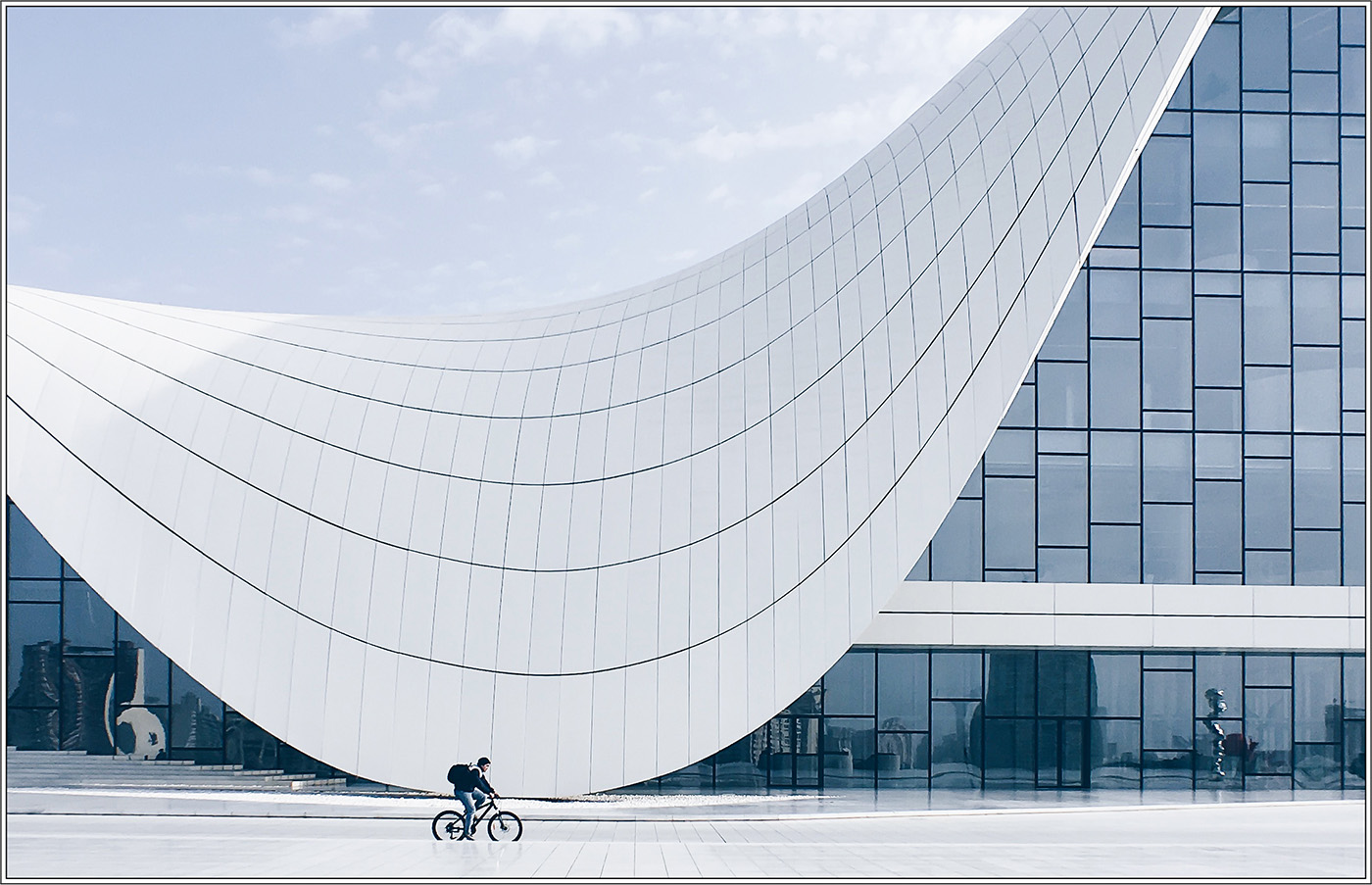

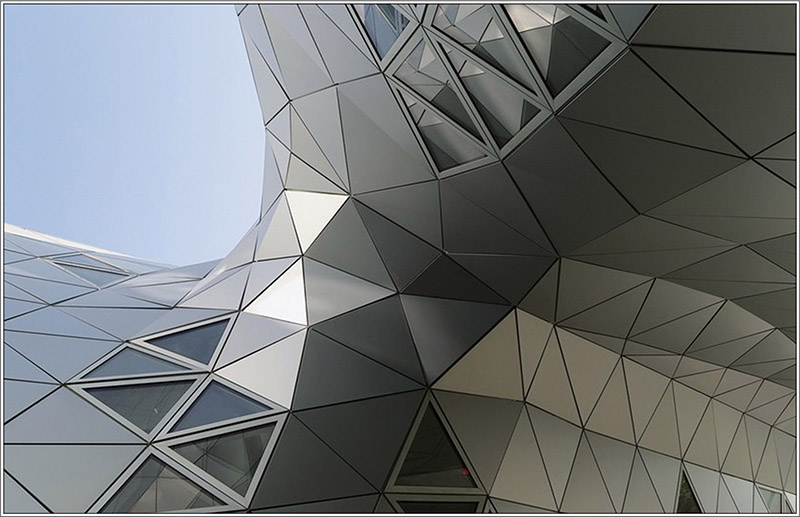

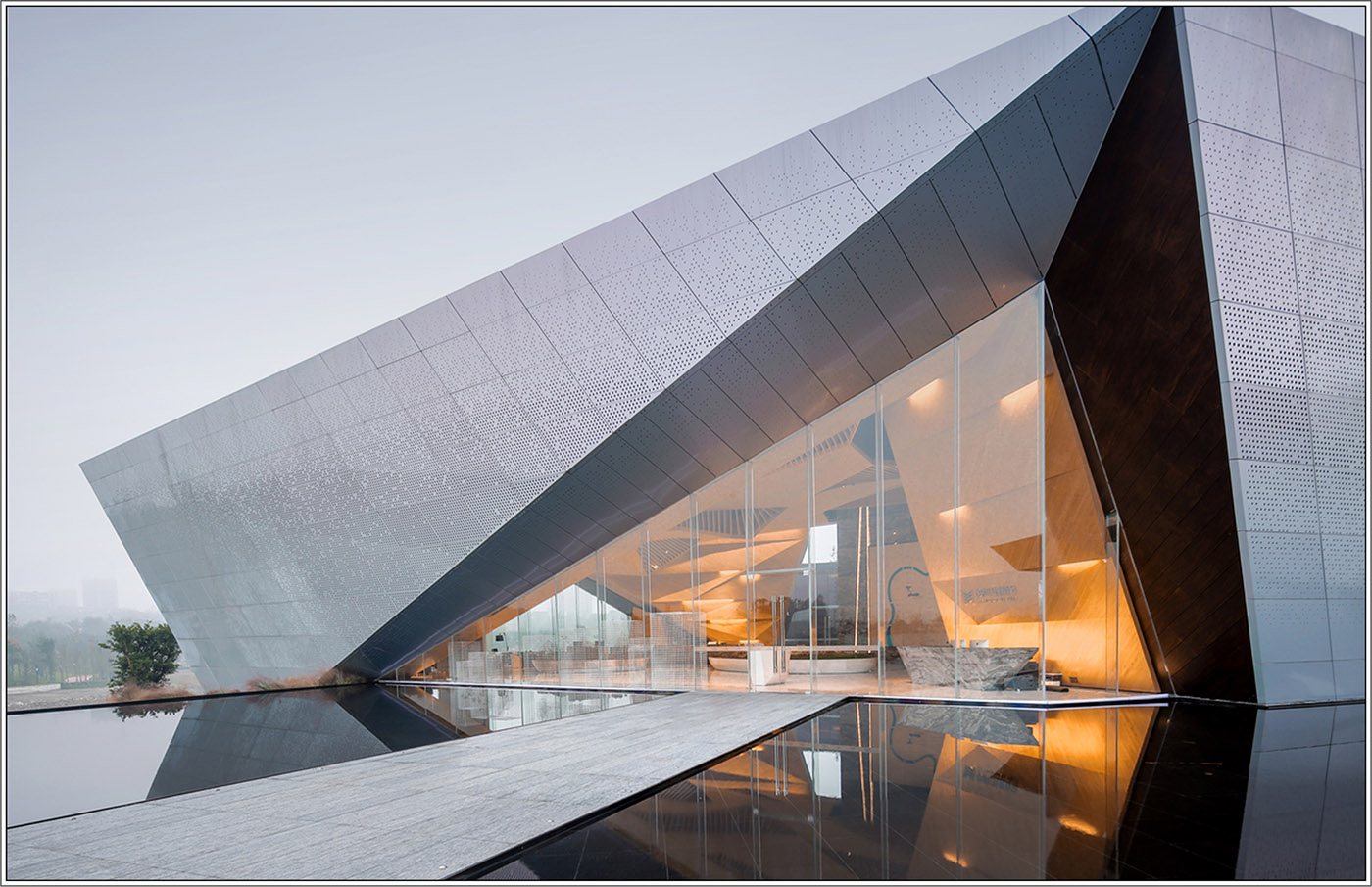

Outdoor aluminum curtain walls

Aluminum curtain wall is light weight, high strength, good rigidity and rich colors, color consistency is good. High anti-corrosion, waterproof, prevent chemical corrosion. Plasticity is good, easy to fastening and installation. Superior performance and safety, which can adapt to all kinds of extreme climate conditions. At present it has been widely used in city landmark buildings, railway stations, fitness center, exhibition center and other large construction engineering project.

Applicable places: senior office buildings, corridor, railway stations, factories, hospitals, clubs, banks, shopping malls, exhibition hall, etc.

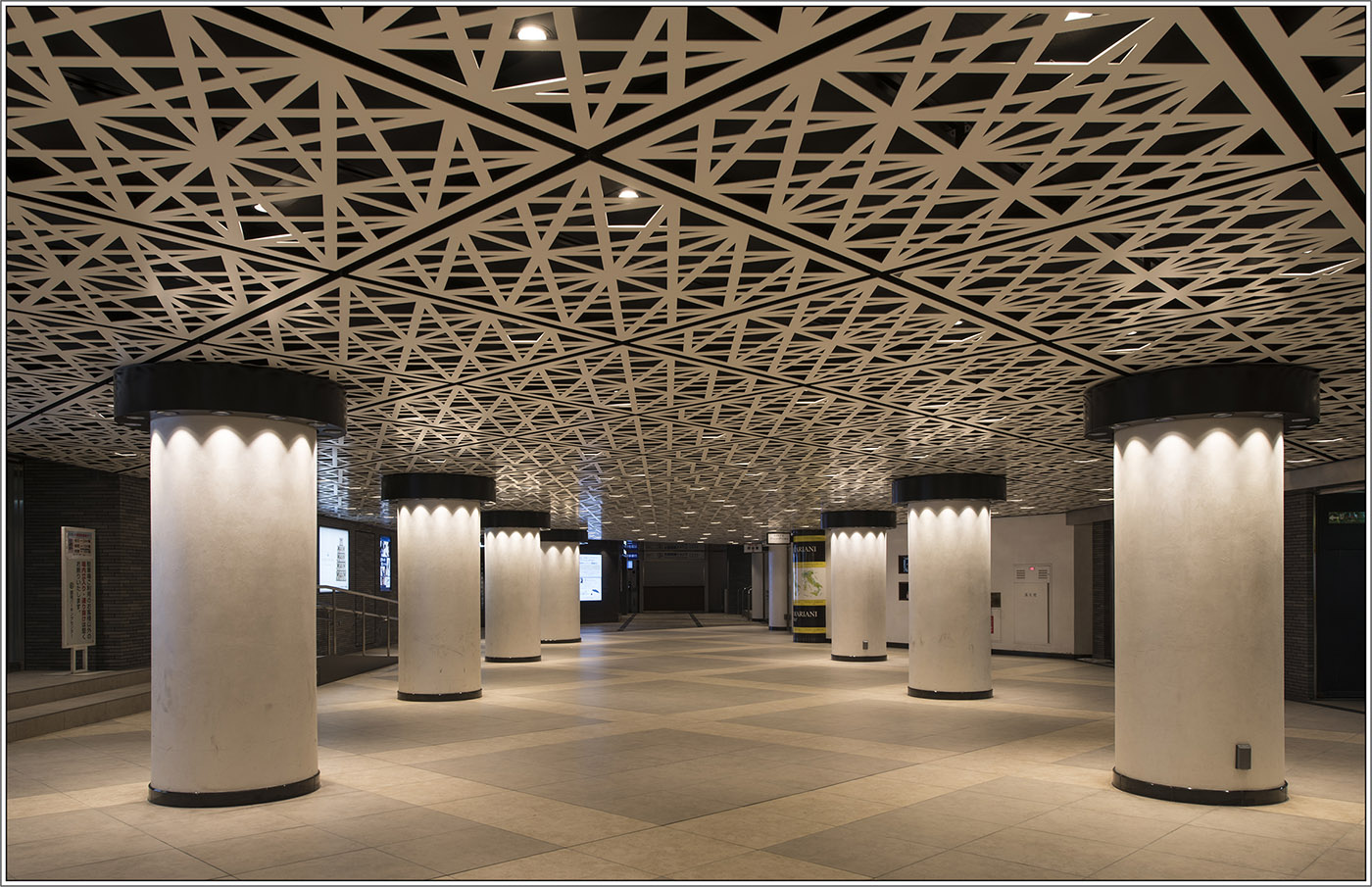

Art aluminum veneer

Using engraving or punching forms to fabricate various patterns pane, make the plane constantly extend and with light, ventilate effect. Different patterns, size and density of the hole shape changes match the surface. Combined with different shape environment for irregular processing, make lines more lively, elegant. Break through the traditional modeling concept, more suitable for all kinds of modern senior clubs, home decoration, office and other places.

Features and advantages

Elegant and noble, beautiful and generous, durable and different shapes, can create new style ceiling effect. Rich modeling express the space and provide a wide range of choices for professional designers. It is the best choice for permanent large buildings.

Applicable places

Large commercial office buildings, municipal office projects, exhibition centers, large venues, senior clubs, etc.

Art aluminum veneer

Using engraving or punching forms to fabricate various patterns pane, make the plane constantly extend and with light, ventilate effect. Different patterns, size and density of the hole shape changes match the surface. Combined with different shape environment for irregular processing, make lines more lively, elegant. Break through the traditional modeling concept, more suitable for all kinds of modern senior clubs, home decoration, office and other places.

Column cover curved panel

With the innovative technology, the launch of a new generation of column cover curved panel can be tightly wrapped in various sizes of the main column, cylinder. Edge design is exquisite, seamless, moisture-proof effect is remarkable, suitable for luxury clubs, museums, sports centers and other large construction projects.

Application

The aluminum veneer is widely used in the interior and exterior decoration of families, office buildings, hotels, shopping malls, office buildings, exhibition centers, public Spaces, etc.

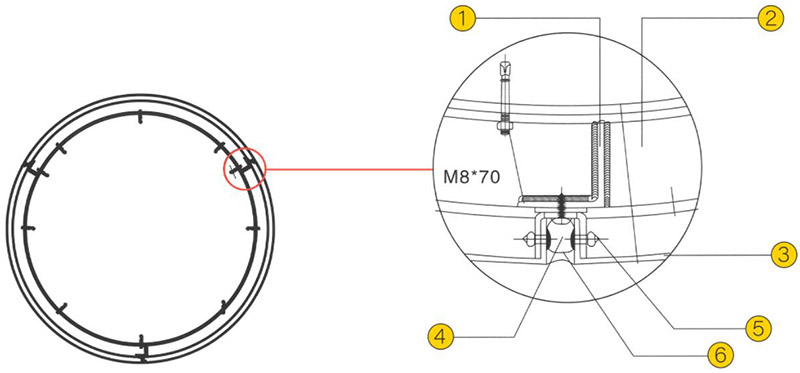

Installation node figure

Installation node figure

1.Vertical angle steel (or steel square tube) 38X38X3 galvanized

2.Circular angle steel transverse bone (or steel square tube) 38X38X3 galvanized

3.Aluminum veneer

4.Foam stick

5.Aluminum corner

6.Seal gum

Special shape aluminum veneer

Modelling ceiling and hyperbolic board are in the same vein. Hyperbolic plate in the overall splicing needs to consider the size of the more accurate and the molding plate needs to highlight its shape, color and rendering. It can give more space to design the intelligence of architecture, many wonderful buildings are reflected in the form of modeling. We believe that in the future architectural design will give building materials more technical and processing challenges, and we will think more about the processing and production in the cost of moulding board.

Baked porcelain aluminum veneer

Using advanced ceramic systems, the coating is specially developed for the outer surface of the aluminum plate in order to perform its unique functions. Porcelain coating systems have durability, chemical resistance, good hardness and absolute fire resistance. Therefore, it can be permanently damaged by sun exposure, bad weather, acid rain, wet environment, automobile exhaust, industrial pollution and other substances. In particular, it is easy to clean

Packaging & shipping

Free Customized Design

We design complex industrial buildings for clients using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)and etc.

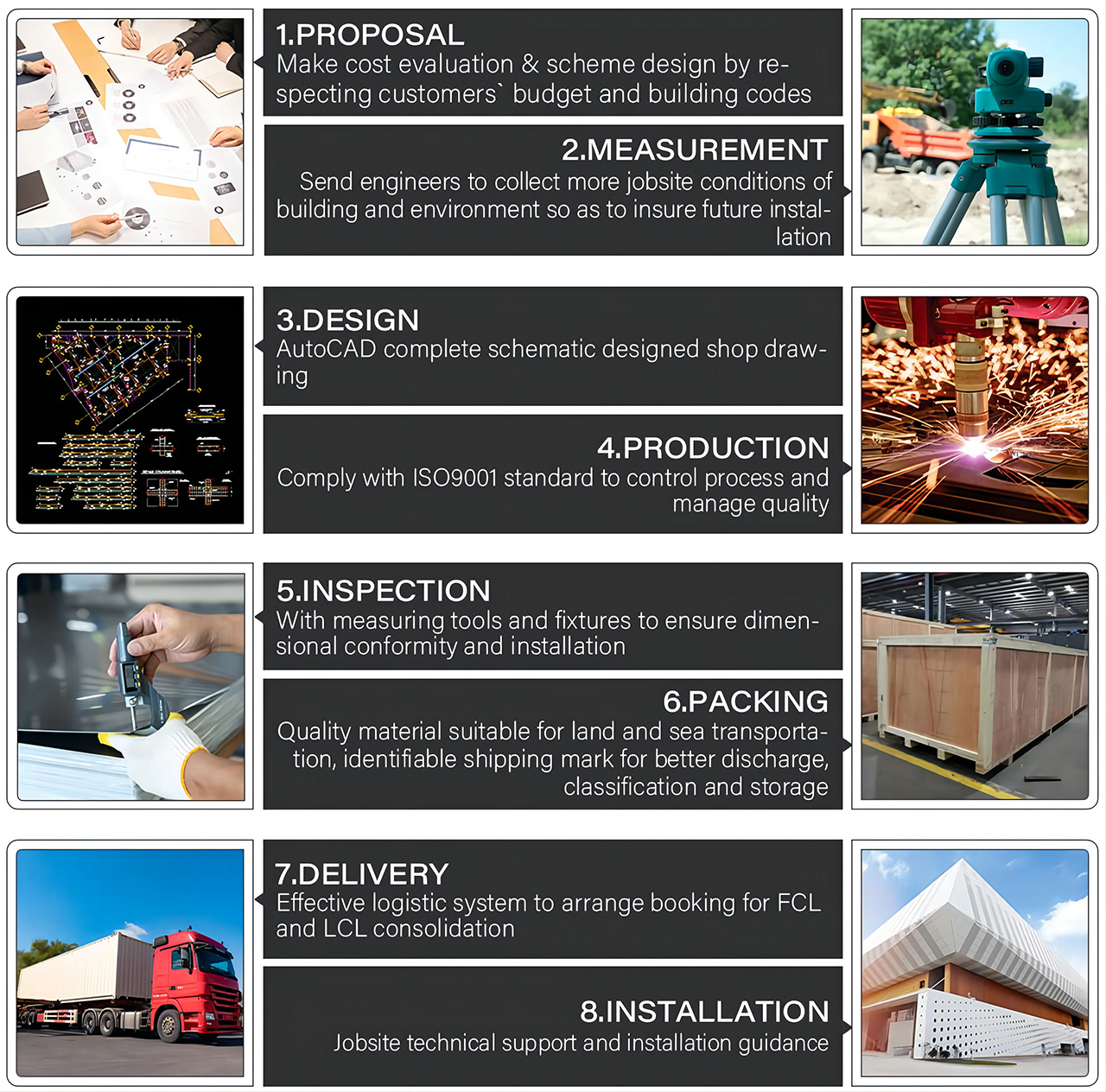

Customization process

Production Workshop Overview

Iron Workshop

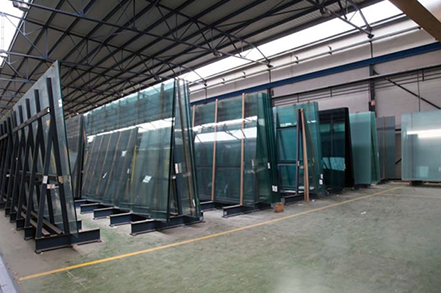

Raw Material Zone 1

Aluminum alloy workshop

Raw Material Zone 2

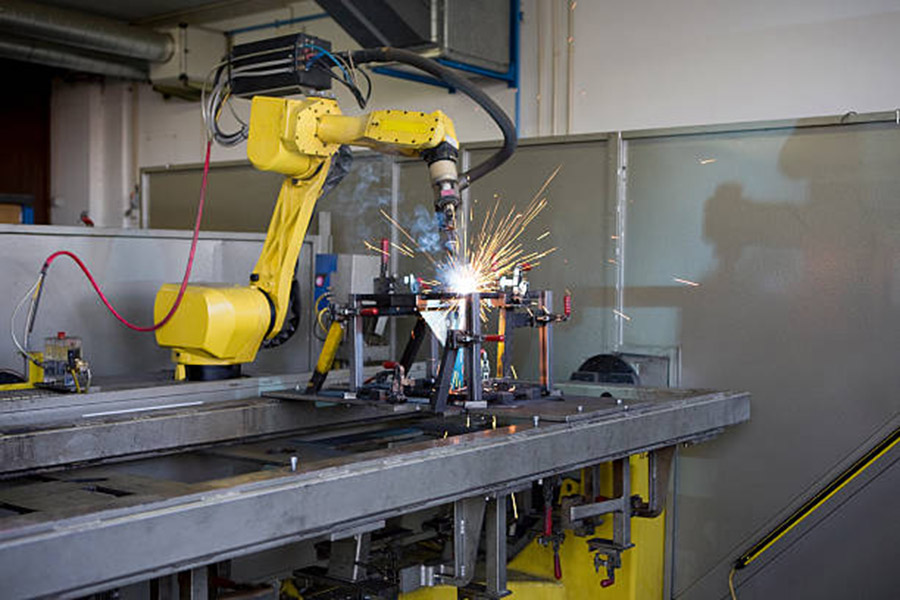

Robotic welding machine installed in new factory.

Automatic Spraying Area

Multiple cutting machines

Our Services & Strength

• Comprehensive manufacturer that provides doors and windows, glass facade system, railings as well as steel structure.

• 35,000 square meters and owned 400 employees & experienced engineering team.

• Large automatic hardware surface treatment production line, including automatic degreasing, rust removal, spraying and the whole line is 450 meters long.

• One stop service, proposal→site measurement→design→production→installation.

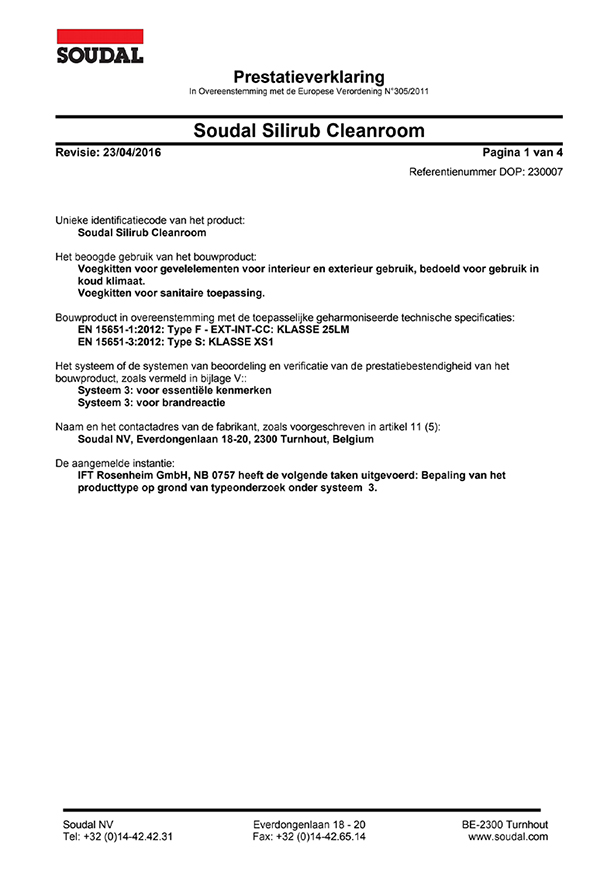

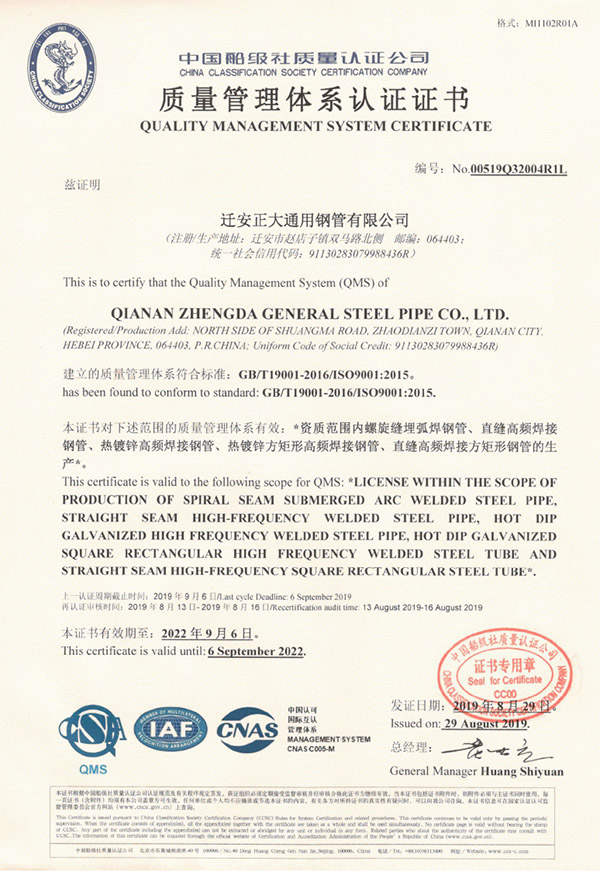

• ISO, CE&SGS qualification certificates.

• Cooperated clients: China's TOP10 real estate development companies such as Country Garden, Sunac, Agile Property.,etc.

• The monthly production value is over 4 million US dollars.

Certification authority

fAQ

1.What’s your manufacturing time?

38-45 days depends upon down payment received and shop drawing signed

2. What makes your products different from other supplier?

Strictly quality control and very competitive price as well as professional sales and installation engineering services.

3. What the quality assurance you provided and how do you control quality?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc

4. How to get the accurate quotation?

If you can provide the following project data, we are able to offer you with accurate quotation.

Design code/ design standard

Column position

Maximum wind speed

Seismic load

Maximum snow speed

Maximum rainfall

Cooperative company