Multi Storey Steel Structure Building & Hotel &Office & School & Library & Shopping Center High Steel Structure Building

Characteristics of Multistory Structure

1.Great steel ductility, good seismic performance of the structure

2.Light weight, the weight of steel structure tall building is about 60% of the concrete structure, which could greatly reduce the cost of foundation and structure.

3.Short construction period, the construction speed of steel structure is about 1.5 times faster than that of reinforced concrete structure due to its high degree of factorization.

4.Small structure area, steel column area is about 1/3 of the concrete column and save 3% of the building area

5.Lower the storey height, steel beam sections are generally shorter than concrete and the pipeline can pass through the web of the steel beam. The same height allows more floors to be designed to increase the floor area.

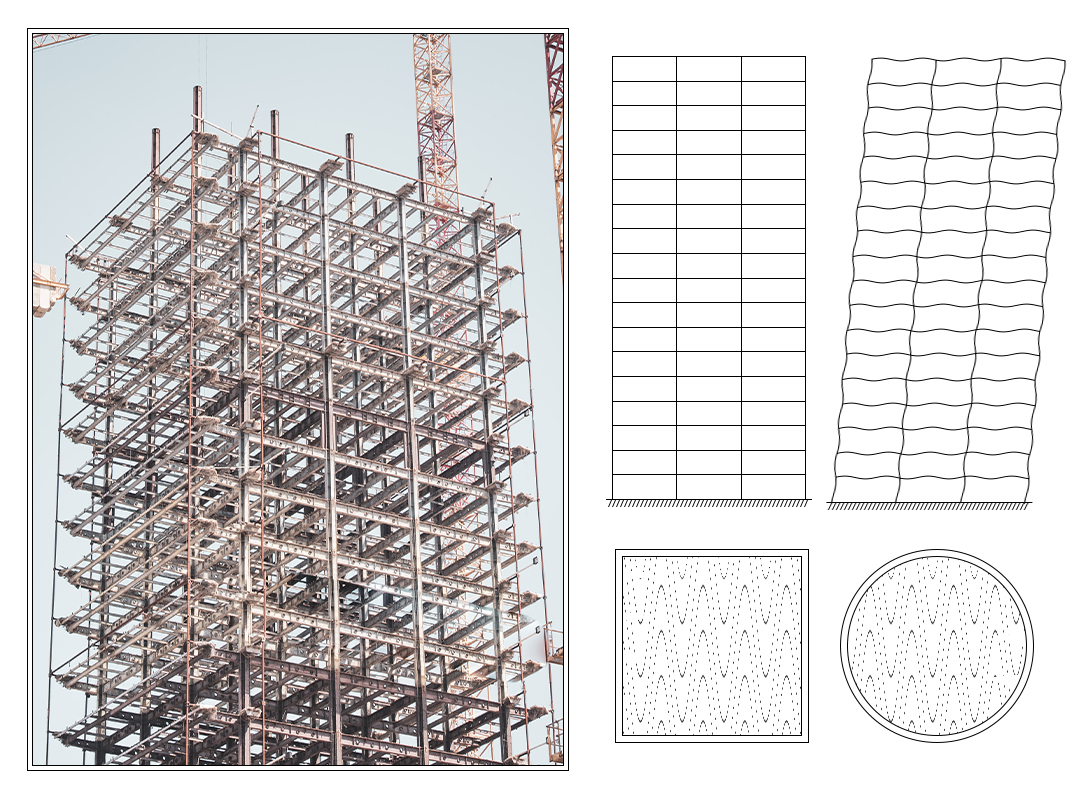

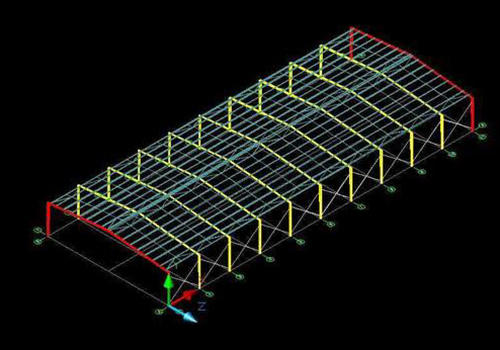

Frame Structure

1.The frame is composed of columns and beams, bearing vertical and lateral forces

2.The performance of rigid frame against lateral force is poor, the lateral deflection of the structure is large, generally suitable for the structure of below 20 stories

3.The column generally uses box steel column or concrete filled steel tube column

4.The concrete-filled steel tubular column is filled with concrete in the round pipe or box column, which not only has the advantages of steel structure, but also makes full use of the good compressive properties of concrete.

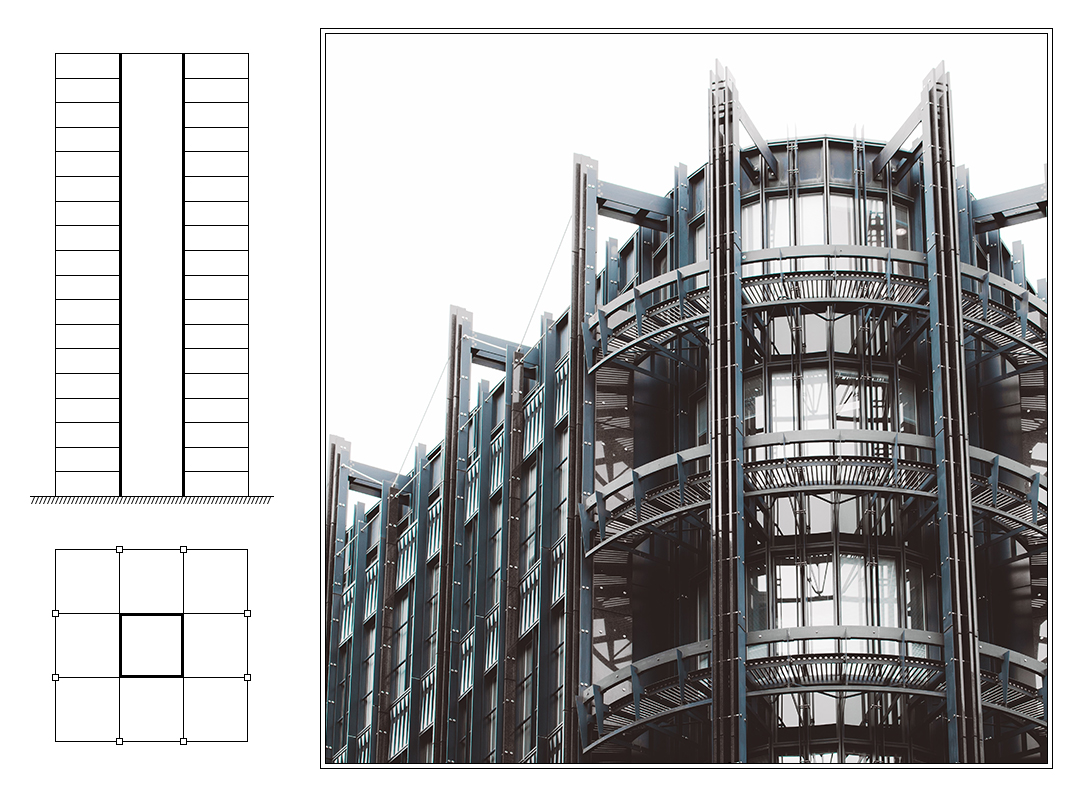

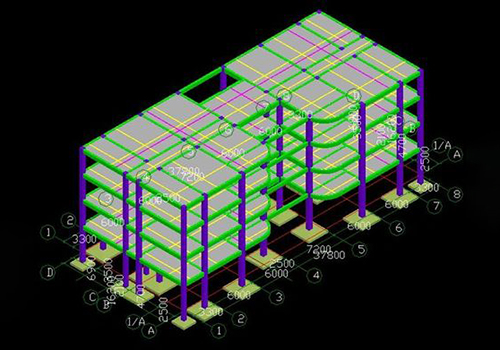

Framed-Tube Structure

1.This kind of structural system is generally composed of reinforced concrete core tube and outer steel frame.

2.The core tube is a square, rectangular or polygonal cylinder surrounded by more than four reinforced concrete walls, the interior is provided with a certain number of longitudinal and transverse reinforced concrete partitions. When the building is tall, a certain number of steel frames may be set in the core wall;

3.The outer steel frame is made up of steel column and steel beam.

4.The lateral deflection of the building is mainly resisted by the core tube, which is the most commonly used structural system in high-rise buildings

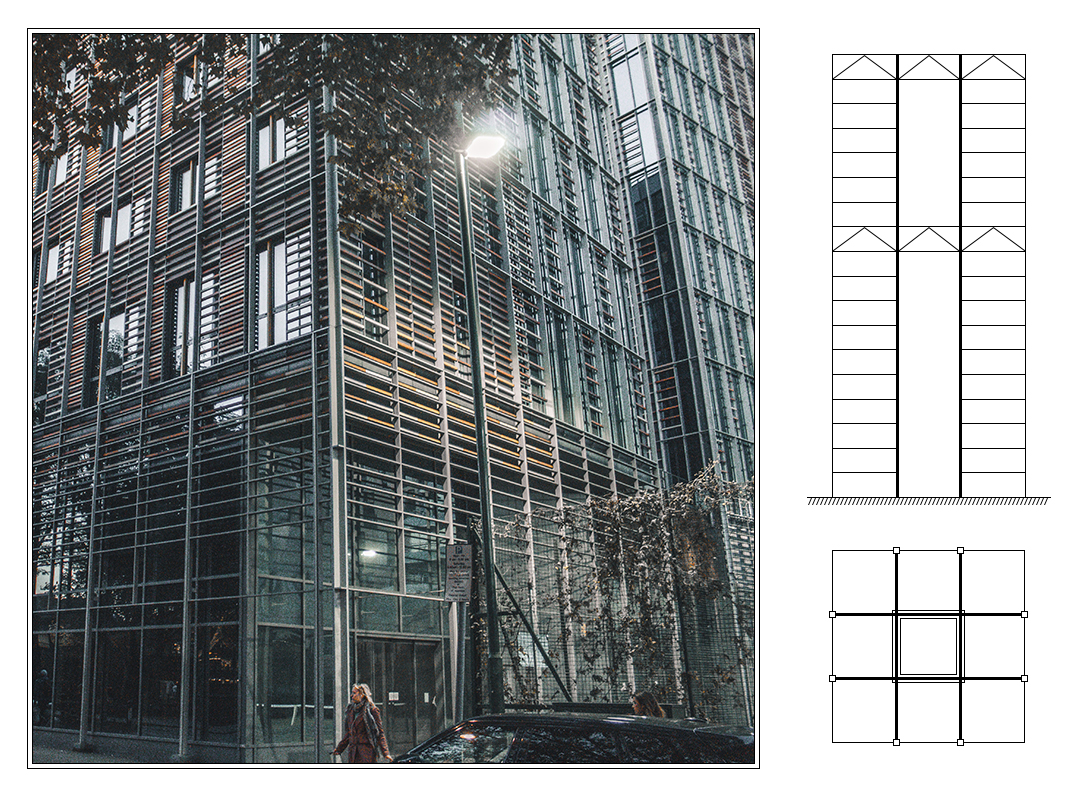

Lateral Force Resistance of High - Rise Steel Structure - Outrigger Truss

1.Outrigger truss is an important measure to reduce lateral deflection of high-rise buildings

2.Outrigger trusses are generally located on the equipment floor or refuge floor, the width through the full width of the house, the height is one or two stories high, generally set up three to four floors in the whole floor height

3.The principle of outrigger truss is that when the building is subjected to lateral deflection, the axial tension force of the outer steel column exerts a reverse torque on the outrigger truss so as to reduce the lateral deflection

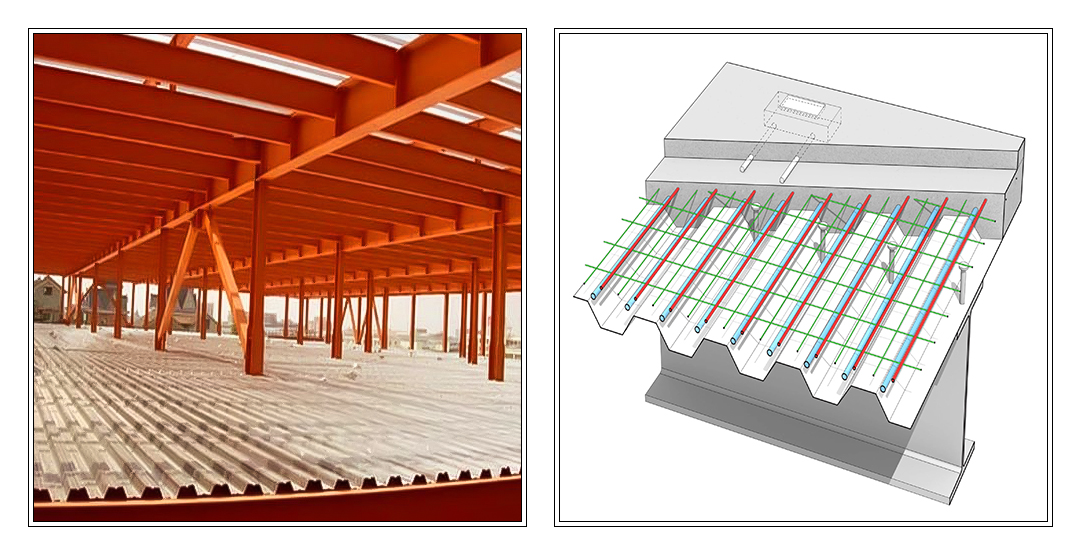

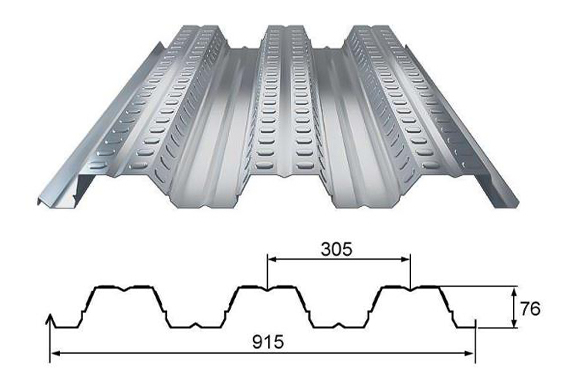

Floor Bearing Plate

1.In order to highlight the advantage of fast construction speed of steel structure, floor bearing plate is generally used in high-rise steel structure

2.When using floor bearing plate, scaffolding or form board is not required. Floor bearing plate can be used as permanent form board, which is high speed of construction and can also partially replace the floor reinforcement.

3.Floor bearing plate is usually open, closed, truss types

Floor Bearing Plate

| Bearing capacity |

|

| Fireproof performance | Floor bearing plate is not fireproof, the bottom of the plate needs to be reinforced, the floor bearing plate does not need to brush fire coating |

| Construction | The laying speed of floor bearing plate is fast, but the binding of steel bar is slow |

| Use | The bottom of the floor has wave-shaped, rough and uneven and the appearance is not smooth enough |

| Economy | Floor slab type utilization rate is high and low price. the bottom recess reduces the amount of concrete used in the floor by about 25, reduce the weight of the building, also save the main structure and basic costs |

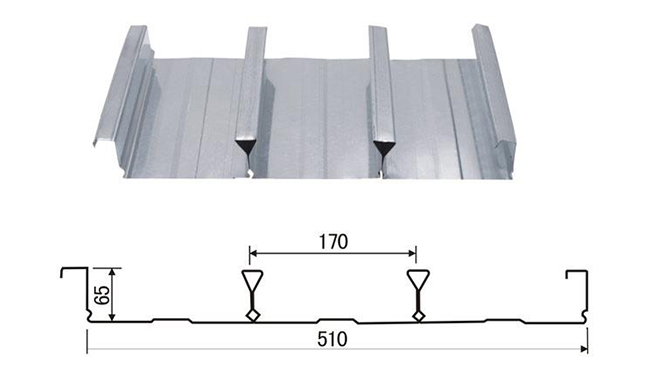

Closed Type Floor Bearing Plate

| Bearing capacity |

|

| Fireproof performance | Floor bearing plate is not fireproof, the bottom of the plate needs to be reinforced, the floor bearing plate does not need to brush fire coating |

| Construction | The laying speed of floor bearing plate is fast, but the binding of steel bar is slow |

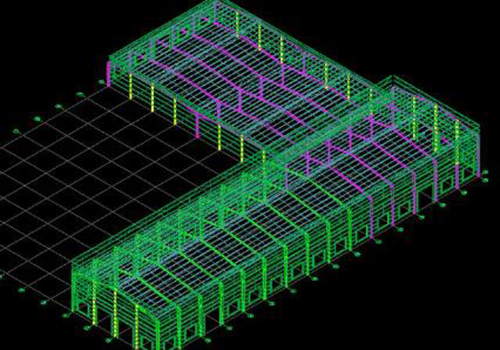

Free Customized Design

We design complex industrial buildings for clients using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)and etc.

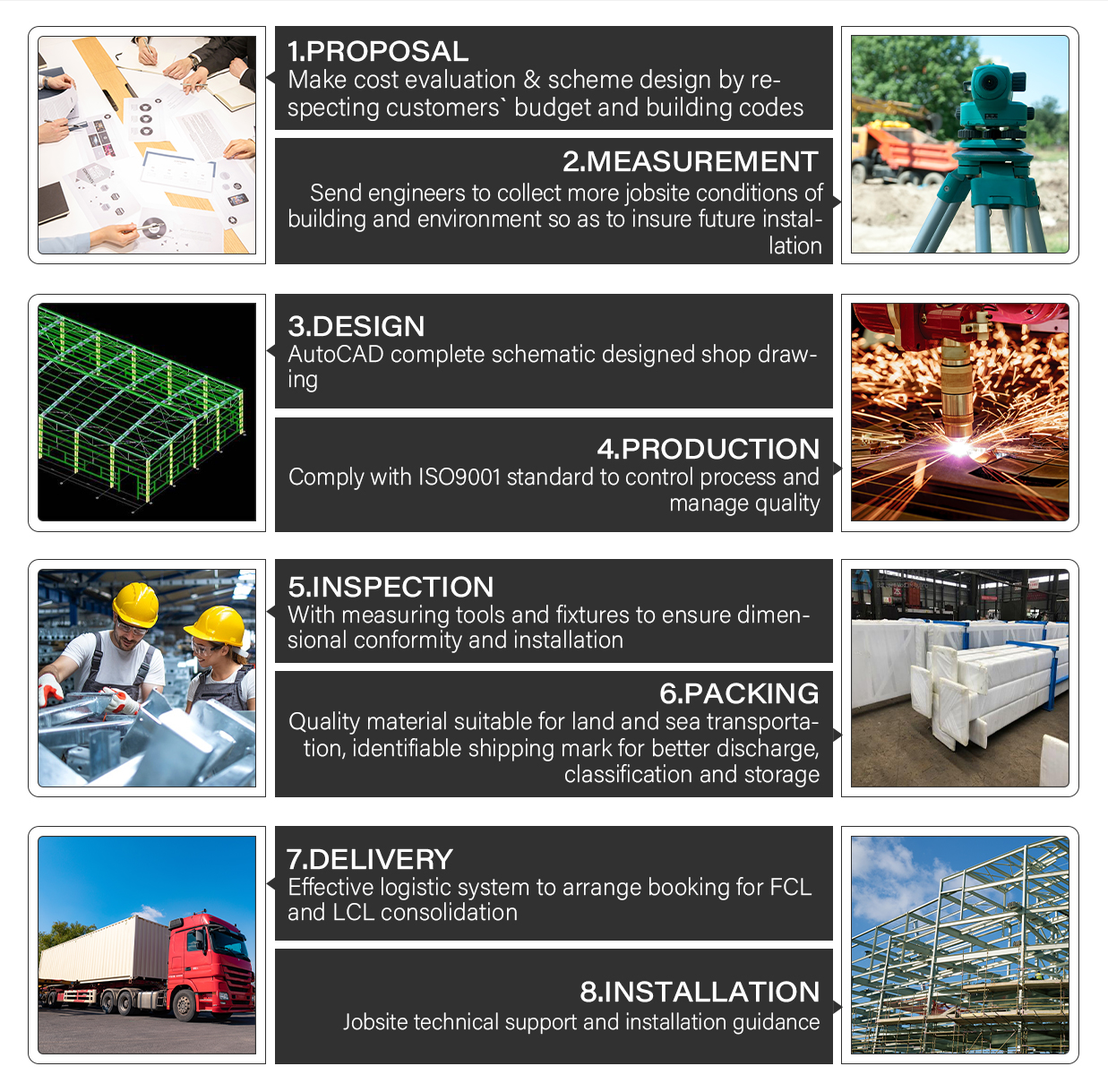

Customization Process

Packaging & Shipping

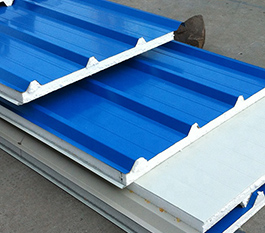

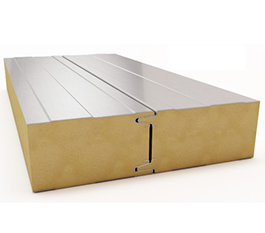

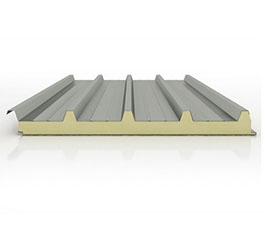

Cladding System

Roof Panel

Roof Panel

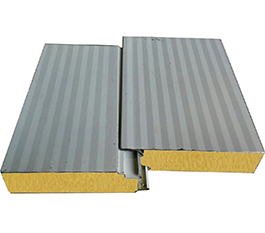

Wall Panel

Wall Panel

Wall Panel

Roof Panel

Fiber-Glass

Steel Sheet

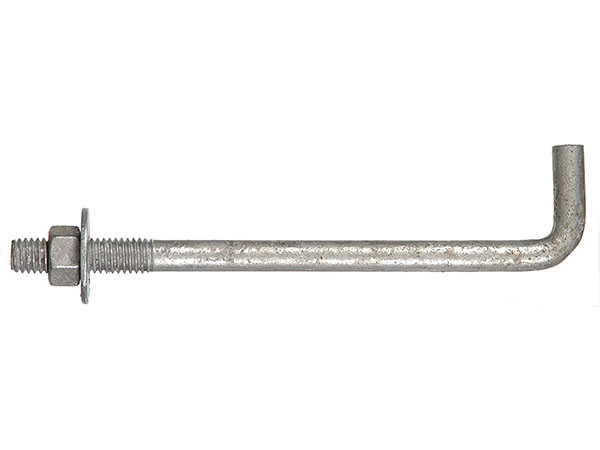

Bolt

Galvanized Bolt

Expansion Bolt

Self-Tapping Screw

High Strength Bolt

Anchor bolt

Stud

Main Products

Steel Prefab Warehouse

Steel Prefab Hangar

Steel Prefab Stadium

Bailey Bridge

Station

Exhibition Hall

Production Workshop Overview

Iron Workshop

Raw Material Zone 1

Aluminum Alloy Workshop

Raw Material Zone 2

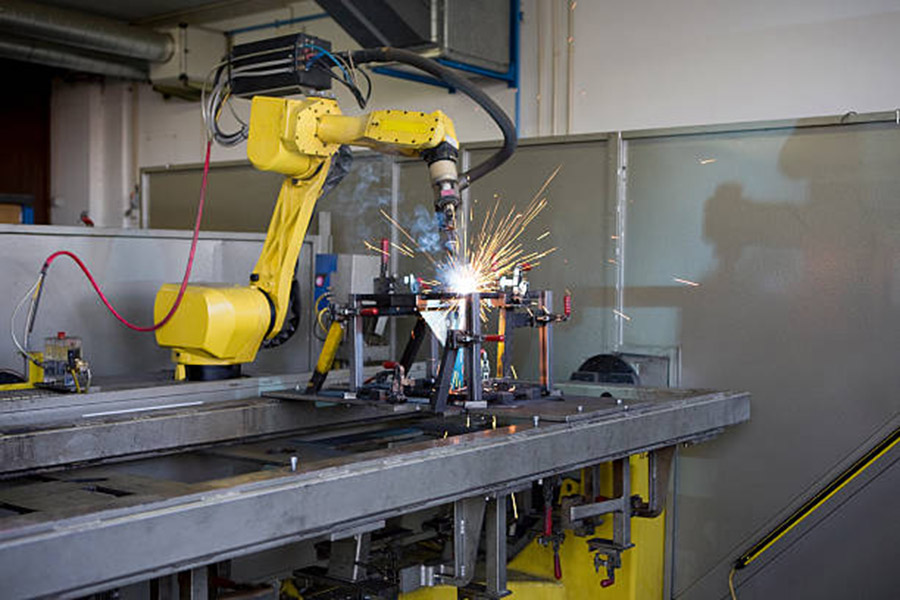

Robotic Welding Machine Installed In New Factory

Automatic Spraying Area

Multiple Cutting Machines

Production Process

1.Prepare Material

2.Cutting

3.Joint

4.Automatic Sub-merged Arc welding

5.Straightening

6.Parts Welding

7.Blasting

8.Coating

Quality Control

Ultrasonic weldina inspection

Ultrasonic welding inspection

Spray paint inspection

Ultrasonic weldina inspection

Certification Authority

Cooperative Company

FAQ

Q: Do you have installation services?

A: Yes, We do have the installation guidance service which you need to pay for the engineer including the Visa cost.round trip ticket,food&accommodation as well as local insurances.

Q: How to get the accurate quotation?

A: The use life of the main structure is the designed used life, usually is 50-100 years (standard request of GB)

Q: How long is the use life of the roof cover?

A: The use life of the PE coating is usually 10-25 years. The use life of roof sun light sheet is shorter, usually 8-15 years

Q: What is the anti-rust treatment for steel structure?

A: Anti-rust treatment of steel structure Normal anti-rust paint

Anti-rust paint with epoxy zinc primer

Hot-dip galvanization

Hop-dip galvanization + PU finish

Powder coating

Stainless steel structure: No. 301/304/316 stainless steel structure

Q: How do we cooperate on some certain projects?

A: We are requesting for the project details and requirements,we will make the design accordingly,then the shop drawings needed to be checked and confirmed if there is no any new update.finally we make a deal.