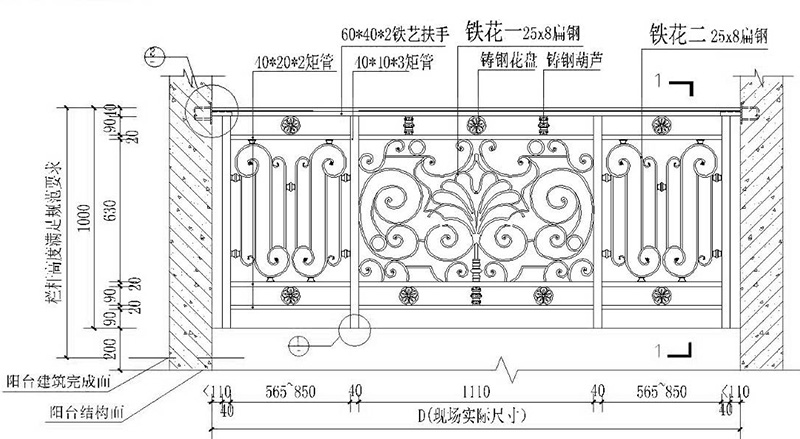

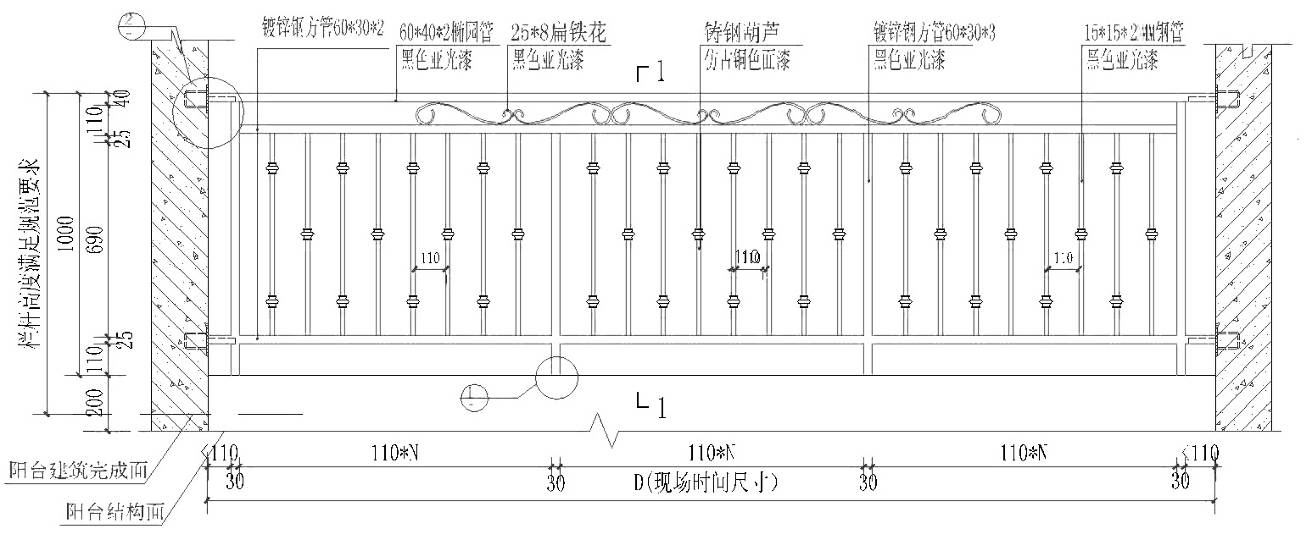

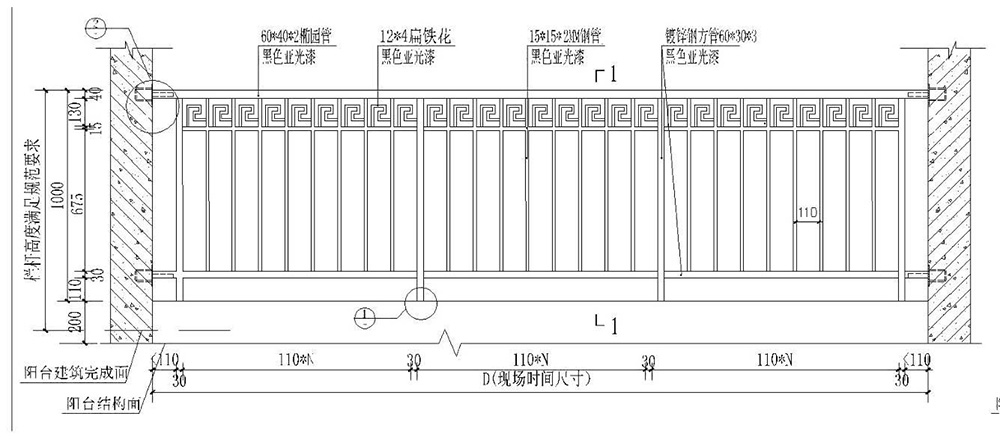

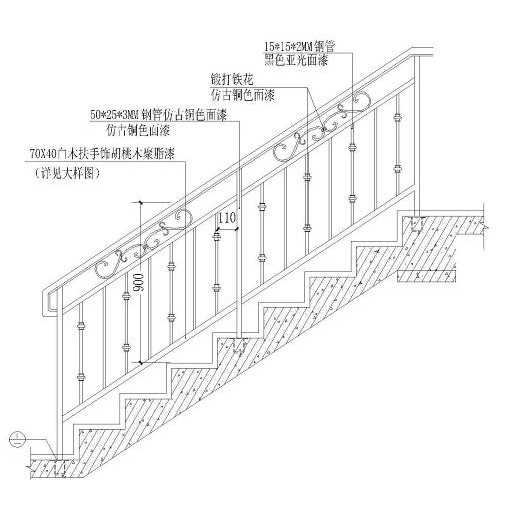

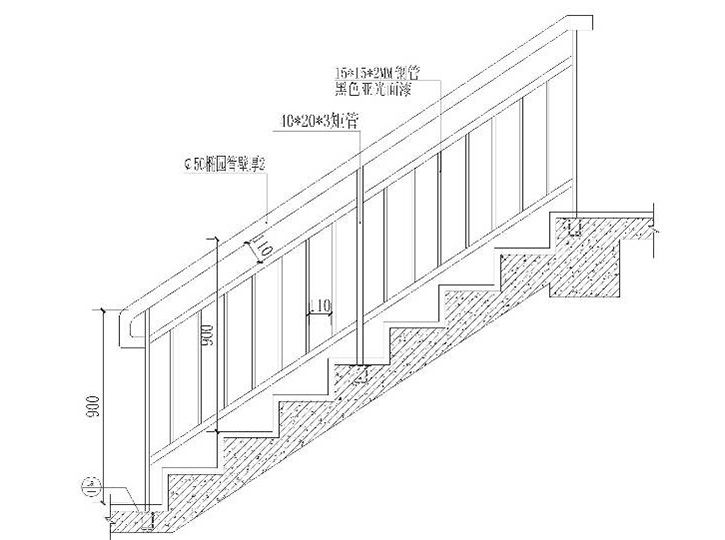

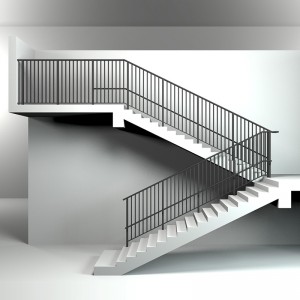

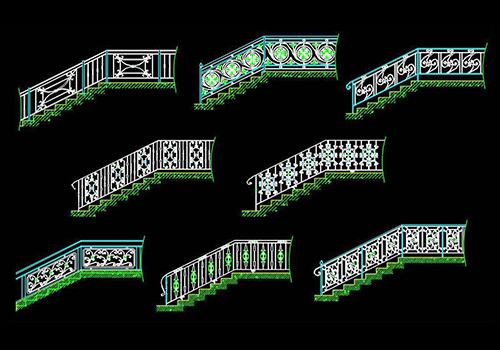

Classic Chinese Handrail Design Wrought Iron Balcony Railing &Exterior Railings

|

Place of Origin: |

Zhongshan,China |

|

Brand name: |

Deshion |

|

OEM/ODM Service: |

Acceptable |

|

Design Style: |

General |

|

Project Solution: |

One-stop solution |

|

Material: |

Wrought Iron |

|

Color: |

Customized |

|

Height: |

Customized |

|

Finish: |

Painted |

|

Payment Terms: |

T/T |

|

Design: |

CAD |

|

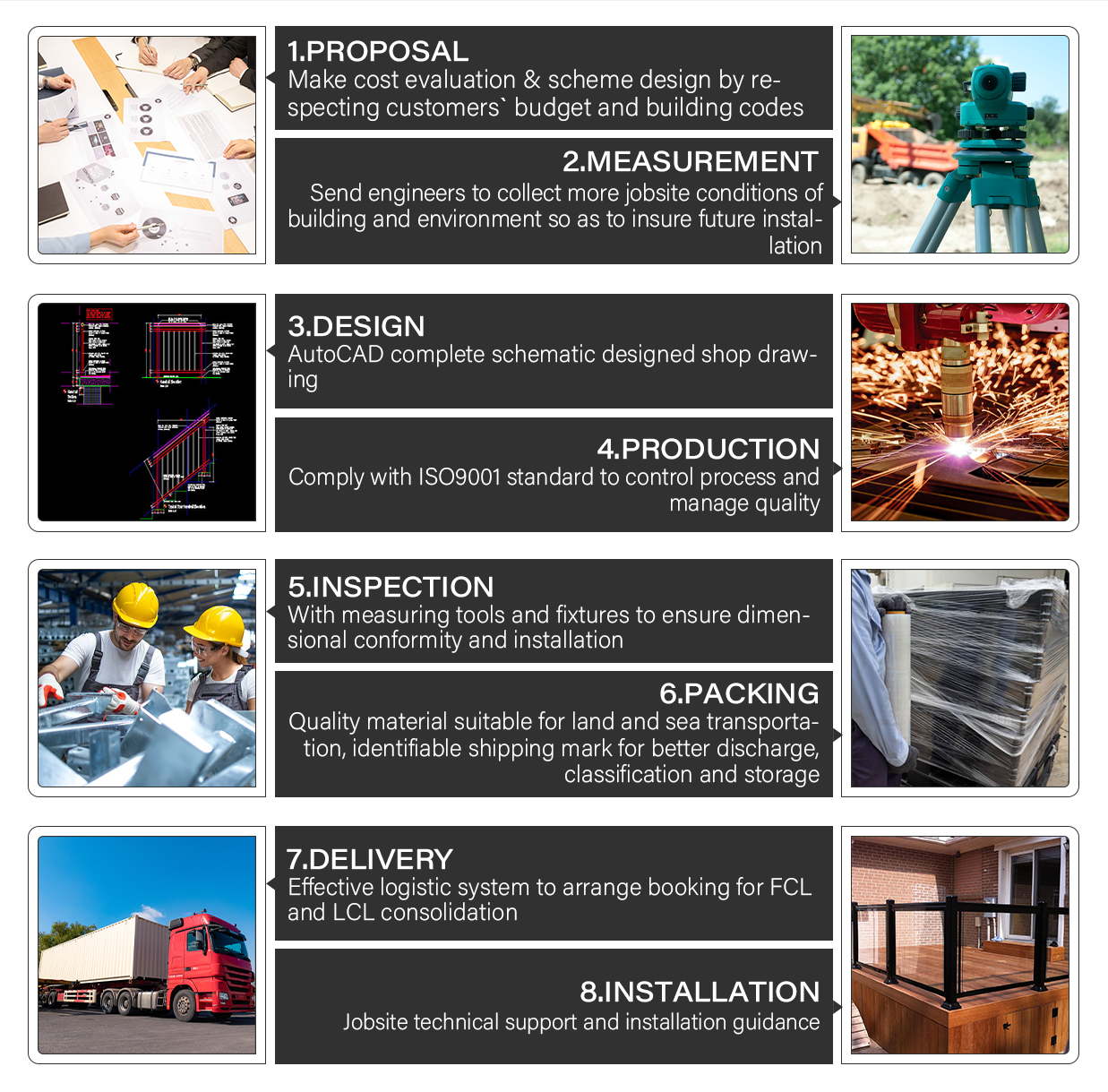

Technical Support: |

Installation Guidance Service |

|

Supply Ability: |

3000m/Monthly |

|

Lead Time: |

30 Days(Below 3000m) Or To be negotiated |

|

Port: |

Zhongshan/Guangzhou/ShenZhen |

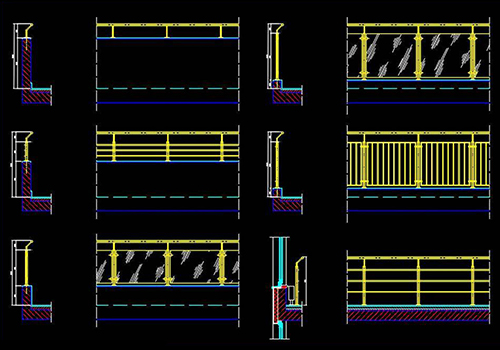

The wrought iron height of residential balcony railing is divided into two specifications: 1000mm and 700mm. The selection principle is as follows:

|

Wrought iron height |

Selection principle |

Remarks |

|

1000mm |

Height of solid part of railing= 200 mm (The solid part has no tread) |

1.Step surfaces should be avoided in the solid part of the railings. If any, refer to figure 3 in attached figure G-02. 2. Individual processing with special requirements for specific projects |

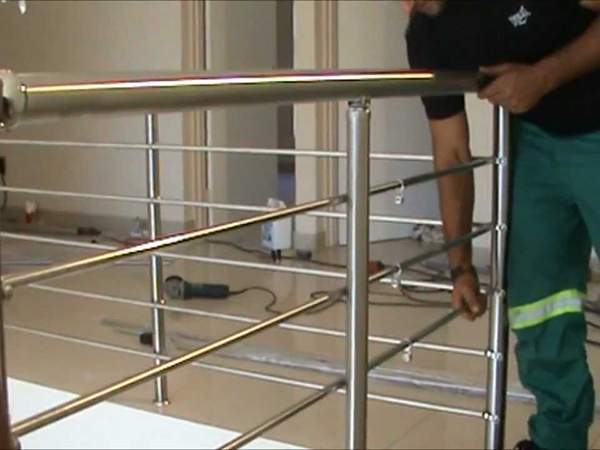

① Stainless steel, section steel, flat steel guardrail column and embedded parts should be fully welded, Q235 steel plate is used for embedded parts and the anchor bar is HPB235 steel bar. Spot welding shall not be used for permanent connection between embedded parts, stressed rod parts and protective rod parts. When bolts or rivets are used to connect the main force bars of the guardrail, there should be no less than two at each connection point.

② The welding place should be full, firm and polished smooth, and there should be no cracks, no fusion and other defects.

③ The steel is made of material. After the whole railings are hot-dipped with zinc (including embedded parts), a layer of zinc-rich epoxy powder is sprayed with a layer of powder thickness ≥0.04mm.

④ Spray uv resistant polyester powder as the surface layer. After the powder ≥0.04mm, The paint color is subject to the physical sample.

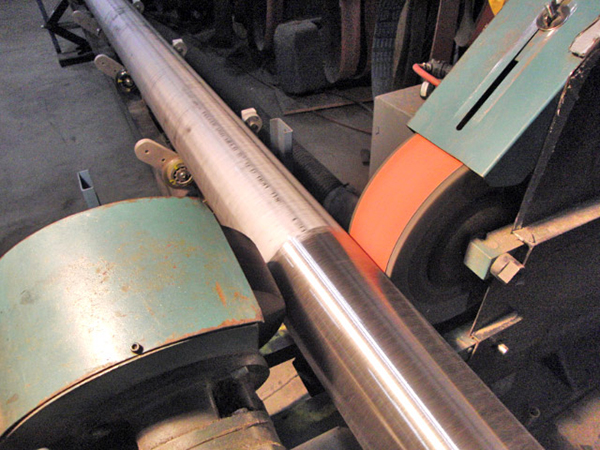

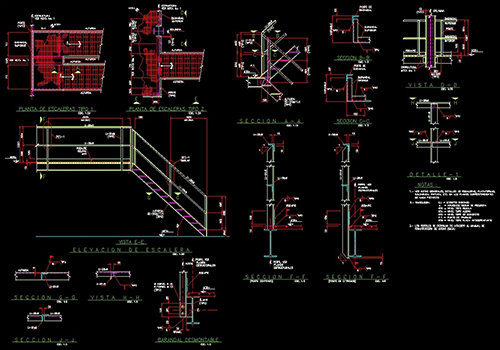

(1) CNC Cutting

(2) Flatten

(3) Fixed Position

(4) Driling & Threading

(5) Welding

(6) Grinding

(7) Polishing

(8) Processing

(9) Assembling

We design complex industrial buildings for clients using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)and etc.

Iron Workshop

Raw Material Zone 1

Aluminum Alloy Workshop

Raw Material Zone 2

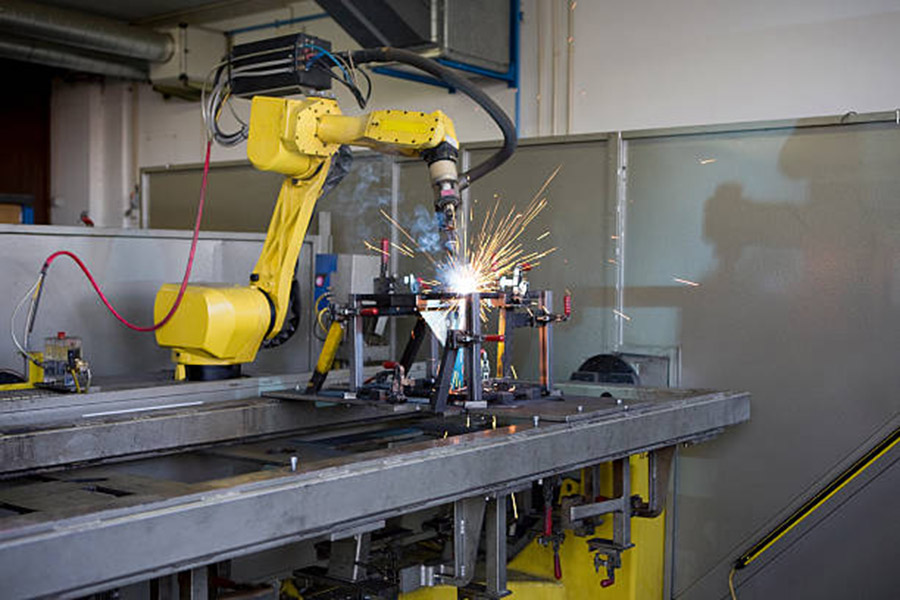

Robotic Welding Machine Installed In New Factory

Automatic Spraying Area

Multiple Cutting Machines

Q:Will you accept small trial order?What’s your MOQ?

A:We do accept small order.MOQ is negotiable,please feel free to contact us for further discussion.

Q:Do you have the customized design service?

A:OEM&ODM are available.Let’s have your design plan and much better have the physical samples.

Q:Is it OK to print my logo on baluster products?

A:Please inform us when you confirm the drawings and samples.

Q:How is the faulty products gonna to be with?

A:Our products will be produced in strict quality control system and the inspection for the defective rate will be less than 0.1%.

Moreover,We will arrange additional small quantity for the spare parts when we shipped the goods.in case if there is any occurred situation on project site.