High-Quality Steel plate curtain wall Factory – Full Glass Curtain Wall System Tempered Cladding Glass Facade Chinese Glass – Deshion

High-Quality Steel plate curtain wall Factory – Full Glass Curtain Wall System Tempered Cladding Glass Facade Chinese Glass – Deshion Detail:

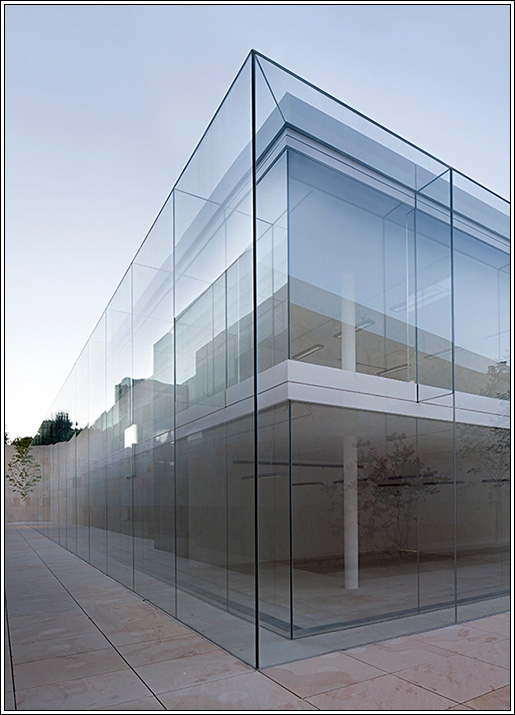

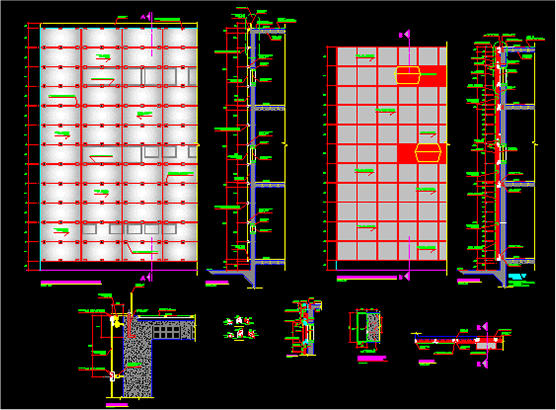

Full glass curtain wall structure

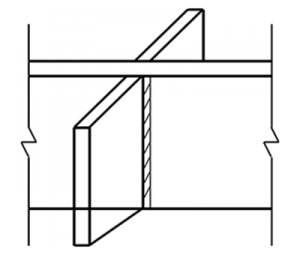

There are two types for full glass facade structure, one is with ribbed glass structure, the other is without ribbed glass.

Ribbed glass: In order to strengthen the stiffness of glass panels, it is necessary to use strip glass as reinforcement ribs at a certain distance, known as ribbed glass

| Maximum height of full glass facade | |||

|

Glass thickness(mm) |

10/12 |

15 |

19 |

|

Maximum height(m) |

4 |

5 |

6 |

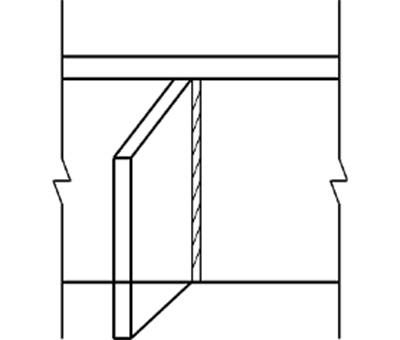

Flooring mounted type full glass facade

Hanging type full glass facade

Full glass curtain wall structure

There are two types for full glass facade structure, one is with ribbed glass structure, the other is without ribbed glass.

Ribbed glass: In order to strengthen the stiffness of glass panels, it is necessary to use strip glass as reinforcement ribs at a certain distance, known as ribbed glass

|

No ribbed glass full glass curtain wall |

|

|

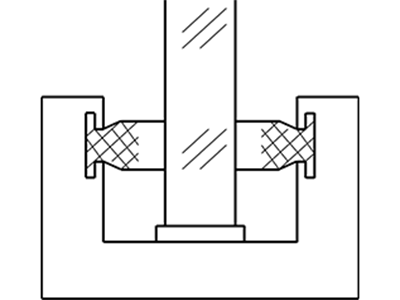

Node structure |

Glass fixed installation method |

|

The common used way is insert the ends of a large piece of glass into metal frame and fix it with silicone structural sealant |

There are three kinds of glass fixed installation method, Dry type assembly, Wet-type assembly, Mixing assembly. |

Dry type assembly

When installing glass, use sealing strips (such as rubber sealing strips) to fix

Wet-type assembly

After the glass is inserted into the slot, use sealant (e.g. silicone sealant) fill the gap between the glass and the tank wall to fix

Mixing assembly

Dry type and wet-type assembly are combined at the same time. First fix the sealing strip on one side, put it into the glass, and finally fix it on the other side with silicone sealant.

Note: the sealing performance of wet type assembly is better than that of dry type assembly, and the service life of silicone sealant is longer than that of rubber sealing strip.

|

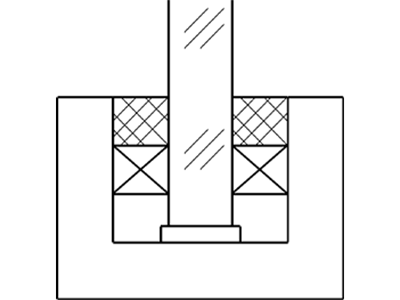

Ribbed glass full glass curtain wall |

|

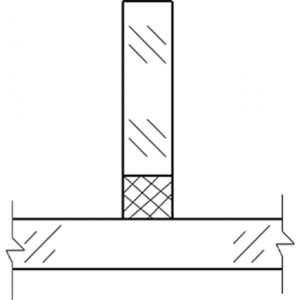

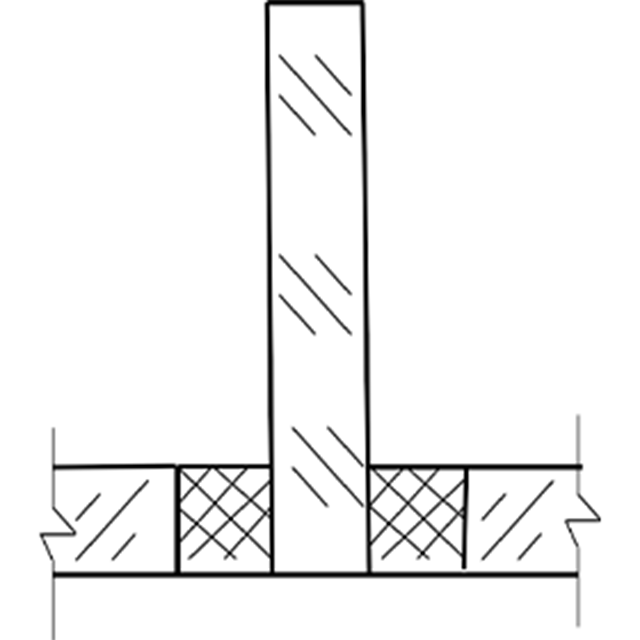

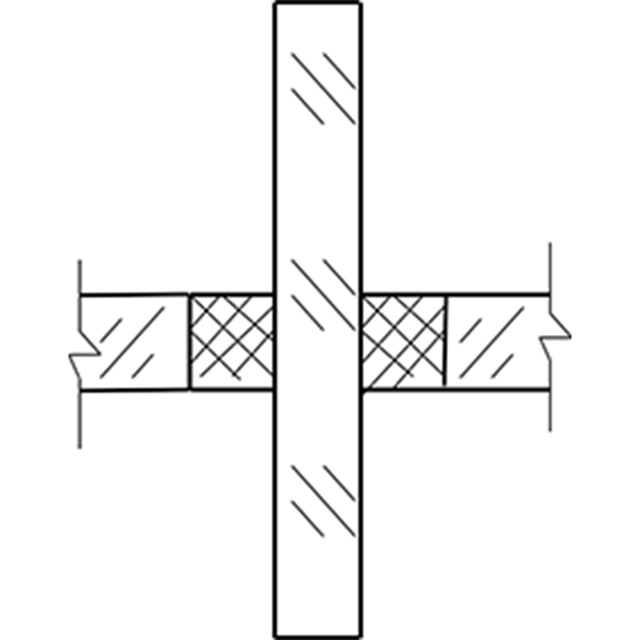

| Intersecting surface structure of ribbed glass | |

| The direction of the rib glass surface is arranged mainly according to the location and function of building, and the artistic requirements. There are usually three structural forms regarding intersection treatment of face glass and ribbed glass: Double ribbed, Single ribbed, Through ribbed. |

Dry type assembly

Ribbed glass on both sides, suitable for middle interior wall

Wet-type assembly

Ribbed glass on one side, suitable for external wall

Mixing assembly

Ribbed glass through the surface glass, suitable for large surface curtain wall.

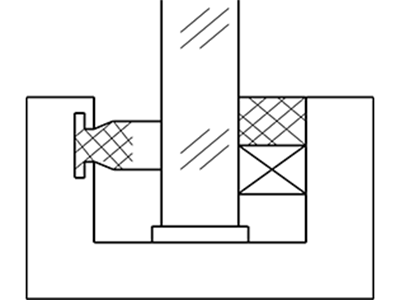

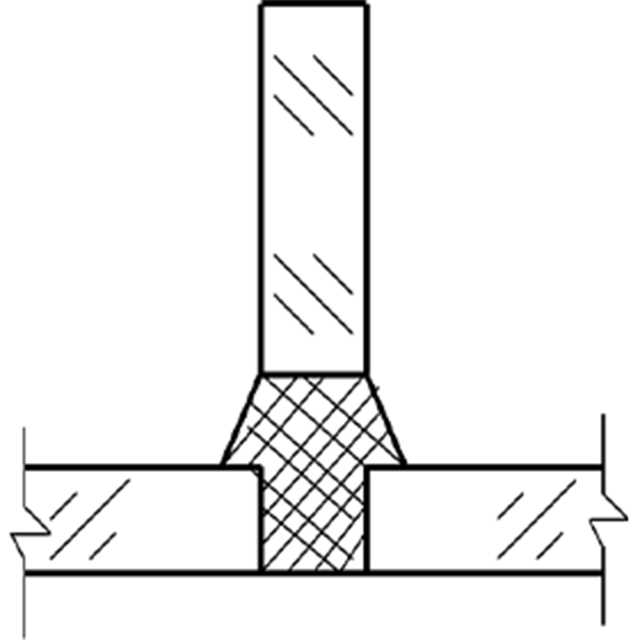

| Intersecting surface treatment of ribbed glass | |

| The face glass and the ribbed glass are connected by transparent silicone structural sealant, and the treatment of the intersecting surface of the ribbed glass is as follows:Rear type, Mounted seam type, Flush type, Protruding type. |

Rear type

The glass rib is located at the rear of the face glass, bonded to the face glass with structural adhesive as a whole.

Flush type

The glass rib is located between two face glass, one side of the ribs is flush with surface of face glass, and the structural adhesive is used between the ribs and two face glass. There would be chromatic aberration in vision due to the different lateral transmittance thickness

Mounted seam type

The glass rib is located at the joint of two face glass, and three pieces of glass are connected together with structural glue

Protruding type

The glass rib is located between the two face glass, both sides protrude surface of face glass, the ribs and the face glass are sealed with structural adhesive.

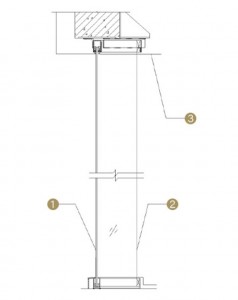

Fixation of ribbed glass full glass facade

Ribbed glass full glass curtain wall

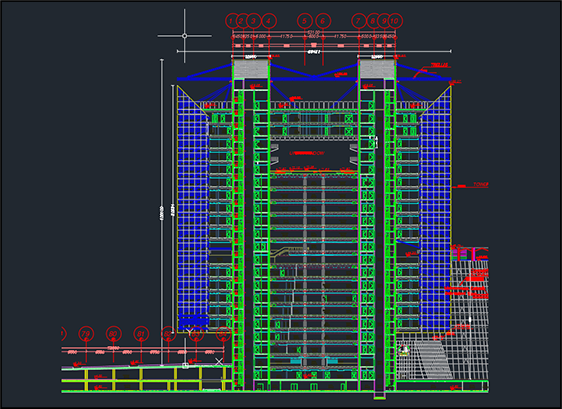

Hanging type full glass curtain wall

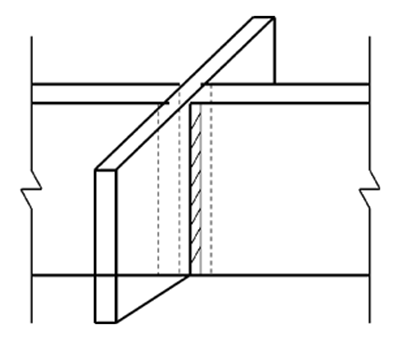

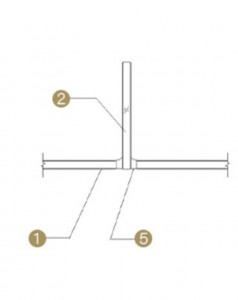

Horizontal node of glass-ribbed all-glass curtain wall

1. Tempered glass; 2. Tempered glass rib; 3. Stainless steel hanging clamp system;

4. Indoor ceiling line; 5. Structural glass glue

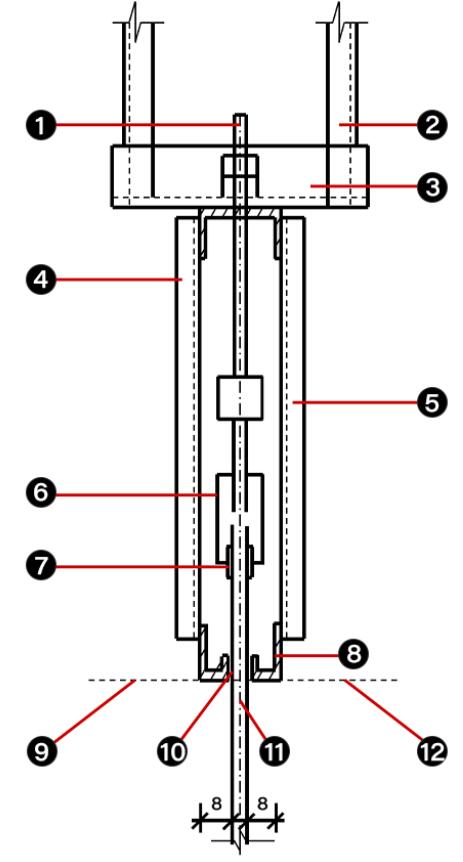

1.Hanging type full glass curtain wall

The structure of hanging glass curtain wall is mainly composed of three parts:

1.Upper load-bearing hanging structure: steel hanger, steel beams, suspension hanger, horseshoe hanging fixture, hanging clamp copper, internal and external metal clip, filling and sealing material, weather resistant silicone sealant.

2.Middle glass structure: glass panel; Glass ribbed plate, silicone structural sealant.

3.Lower frame structure: metal frame, neoprene rubber pad, foam filling material, weather-resistant sealant.

1.Bolt installation; 2. teel hanging bracket;

3.Steel beam; 4.External metal clip;

5.Internal metal clip; 6.Slings;

7.Suspension clamp plate; 8.3mm SS channel steel profile;

9.Exterior finish; 10.Silicone sealant; 11.19 mm glass;

12.Internal ceiling;

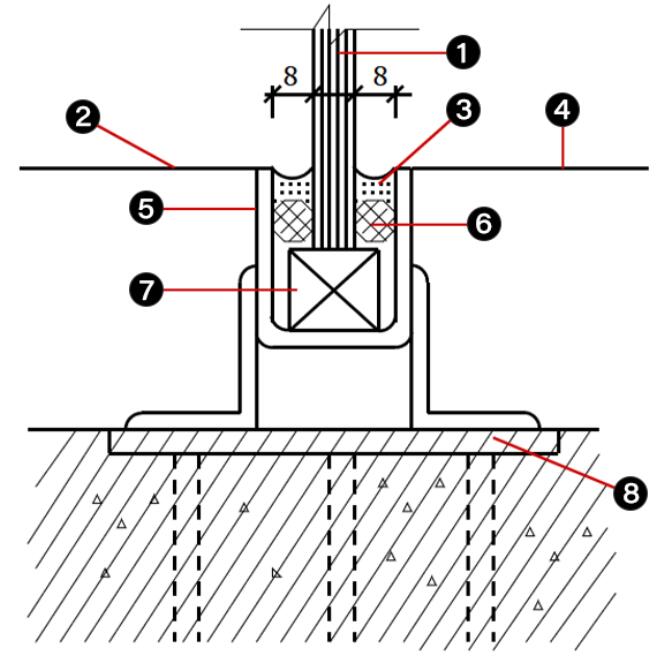

Frame node diagram

1.19 mm glass;

2.Exterior finish;

3.Silicone sealant;

4.Interior surface;

5.3mm SS channel steel profile;

6.Foam filling material;

7.Neoprene spacer;

8.Embedded parts;

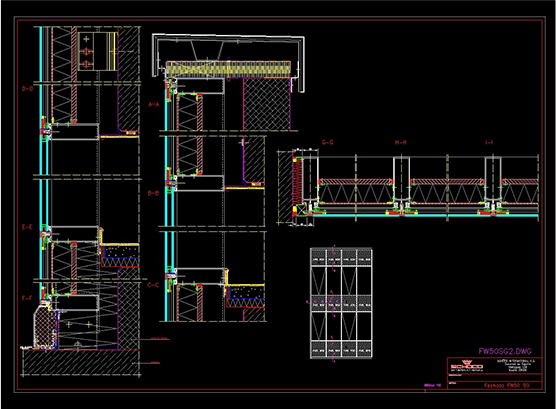

1.The gap between the surrounding closed groove wall and the glass panel or the glass rib should not be less than 8mm, the gap between the lower end of the hanging glass and the bottom of the lower groove should meet the requirements of glass elongation deformation. The glass and the bottom of the lower groove should be supported or filled with an elastic pad and the length of the pad should not be less than 100mm, the thickness not less than 10mm, It shall be sealed with silicone building sealant between the cell wall and the glass.

2.The surface of the full glass curtain wall shall not be in direct contact with other rigid materials. The gap between the plate surface and the decoration surface or the structural surface should not be less than 8mm, and sealed with sealant.

2.The upper bearing hanging structure

1.Steel hanger and beam

Mainly choose structure steel, glass panels and glass ribs and other components of their own mass load and wind load reliably transferred to the main structure.

2.Hanging pole, horseshoe hanging fixture and hanging clip copper sheet

According to the size of suspension load, hanging pole and hanging fixture is divided into ordinary standard and heavy type

| Lifting fixture selection and required construction space height reference table | ||

|

Withstand hanging glass quality(KG) |

Hanging fixture type |

Height of required construction(MM) |

|

Wg<450 |

Standard |

>450 |

|

450≤Wg≤1200 |

Heavy type |

>550 |

3.Internal and external metal clasps

The inner and outer metal clamps are the edge sealing structures on the upper part of the glass curtain wall after the glass suspended, it’s better to choose stainless steel.

3.Material specifications and technical performance

Glass

1.Type:

tempered glass, laminated tempered glass etc.

2.Thickness:

through design and calculation to determine, the more commonly used is 12/19mm.

3.Edge treatment:

should be polished and prevent small gaps after cutting glass, the gap is easy to form stress concentration result in the glass cracking.

1.Strength calculation:

Silicone structural adhesive is used between the face glass and the ribbed glass, the width and thickness of the adhesive joint should be checked by strength.

2.Sealant:

Neutral silicone sealant should be used between glass and metal frame and buckle.

![]()

Metal frame

In the hanging type full glass curtain wall project, the metal frame buried below the ground or in the wall is better to use 3mm thick stainless steel groove steel metal frame.

Installation and construction process of hanging glass curtain wall

Pay-off → Installation of upper bearing steel structure → Lower and side frame mounting → Glass installation → Inject glue and seal → Clean and inspection

Key points of installation

1.Positioning

1. The measuring and laying out of curtain wall positioning axis must be parallel or vertical with the main structure axis, so as to avoid the contradiction between the curtain wall construction and indoor and outdoor decoration construction, resulting in the defects of the Yin and Yang Angle is not square and the decoration surface is not parallel.

2. Use high precision laser level, theodolite, match to standard steel tape, hammer, level ruler to recheck. For the curtain wall with a height greater than 7m, it should be measured and checked twice to ensure the vertical accuracy of the curtain wall. The deviation between the upper and lower center lines must be less than 1 mm to 2mm.

3. The measured lay-off shall be carried out when the wind force is not greater than force 4, the error between actual wiring and design drawing should be adjusted, distributed and digested, it can not accumulate. It is usually solved by adjusting the width of the gap and positioning of the frame. If the size error is large, reflect in time, and remake glass or use other reasonable solution.

5. The all-glass curtain wall is directly fixes the glass to the main structure, first bounce glass to the ground, and then determine the anchorage point according to the outer edge size.

2.Upper steel structure installation

1. Pay attention to check the embedded part or anchoring steel plate is firm, the quality of anchor bolt should be reliable, the location of the anchor bolt should not be close to the edge of the reinforced concrete member, the diameter and depth of borehole should meet technical stipulation of anchor bolt manufacturer, the hole ash should be cleaned up.

2. The installation position and height of each component shall strictly proceed in accordance with the requirements of wiring positioning and design drawings. The most important is that the center line of the load-bearing steel beam must be consistent with the center line of the curtain wall, and the center of the elliptical screw hole should be consistent with the position of the designed derrick bolt.

3. Internal metal clip installation must be smooth and straight. It is necessary to use subsection pull-through line to check and straighten the deflection caused by welding. The outer metal buckle clamp should be assembled according to the serial number, and require straightness. The spacing of internal and external metal clips should be uniform and the size should meet the design requirements.size.

3.Underframe and side frame mounting

Construction in accordance with the wiring positioning and design elevation, all steel structure surface and weld joint brush anti-rust paint. Clean up the dirt inside the lower border. At least 2 neoprene pads should be placed at the bottom of each piece of glass, and the length should not be less than 100mm.

4.Glass installation

Glass lifting and placement shall be carried out in strict accordance with the site construction process

5.Silicone Sealant Injection and Cleaning

The construction thickness of weather resistant silicone sealant should be between 3.5 ~ 4.5mm, too thin sealant joints is unfavourable for the quality of sealing and prevent rain. In addition, the glue injection should not be carried out at a low temperature of less than 5℃, because the temperature is too low, the glue will flow, delay the curing time, and even affect the tensile strength. Stick adhesive tape along the joint position to prevent silica gel from contaminating the glass. Professional rubber injection construction. After the glue injection, use special tools to scrape the glue, makes the glue seam is slightly concave surface. The glass and metal surface of the glue injection part should be wiped clean with acetone or special detergent, do not use wet cloth and water.

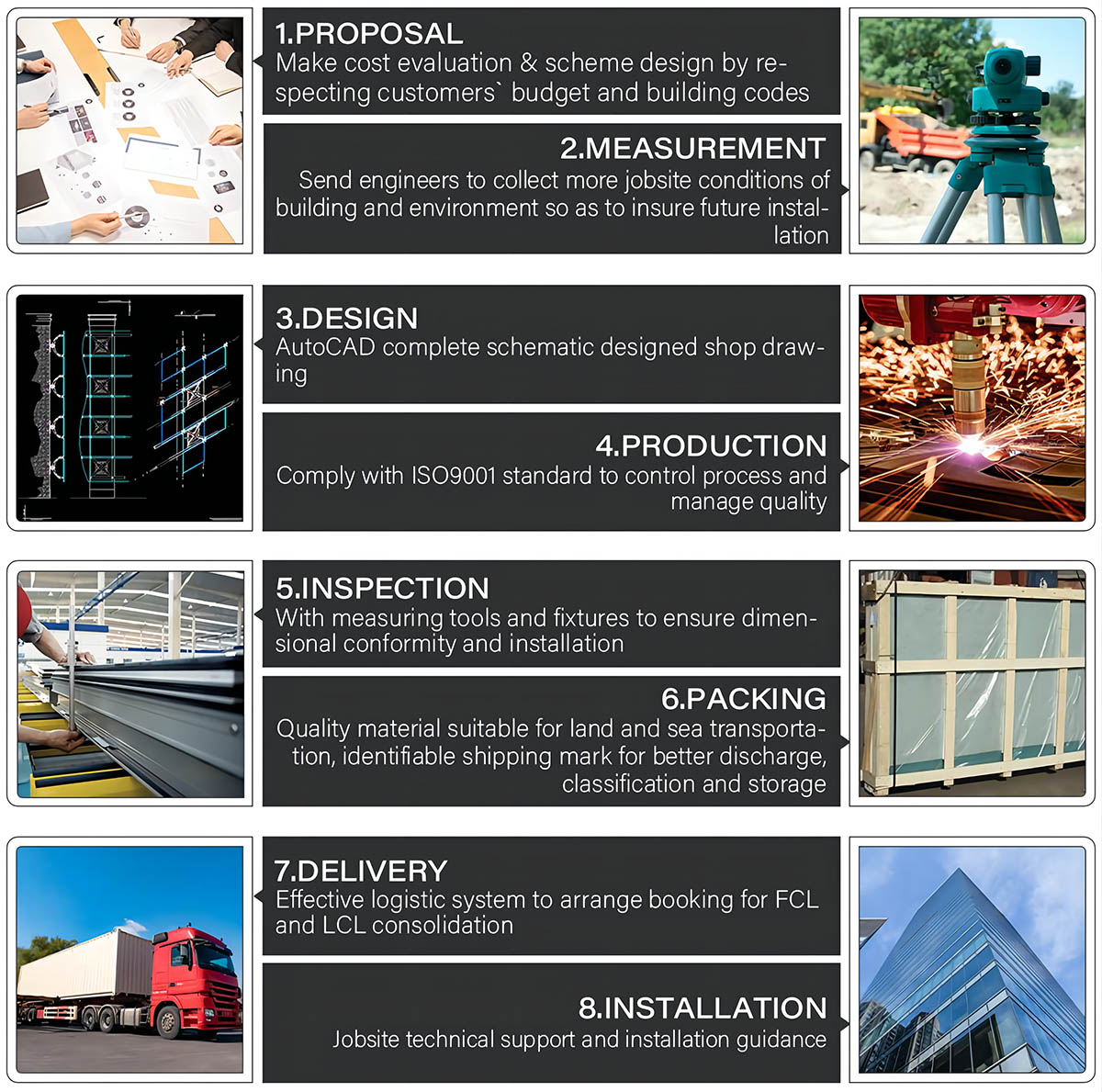

Packaging & shipping

Free Customized Design

We design complex industrial buildings for clients using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)and etc.

Customization process

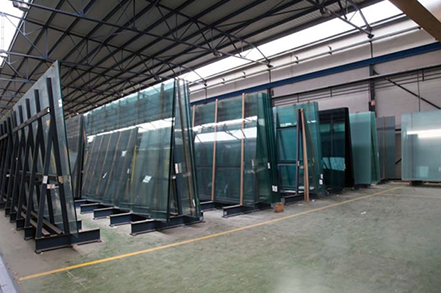

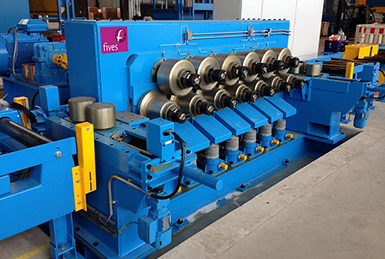

Production Workshop Overview

Iron Workshop

Raw Material Zone 1

Aluminum alloy workshop

Raw Material Zone 2

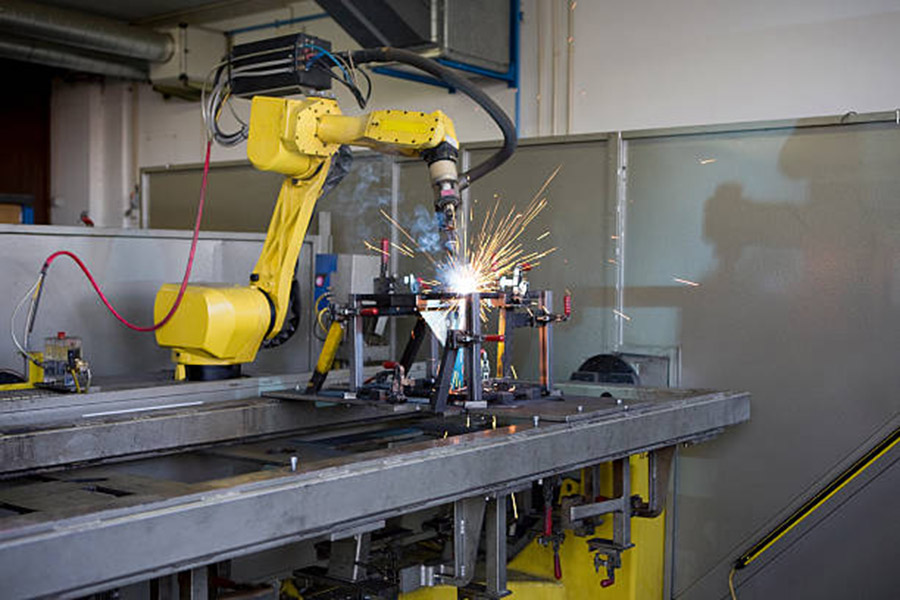

Robotic welding machine installed in new factory.

Automatic Spraying Area

Multiple cutting machines

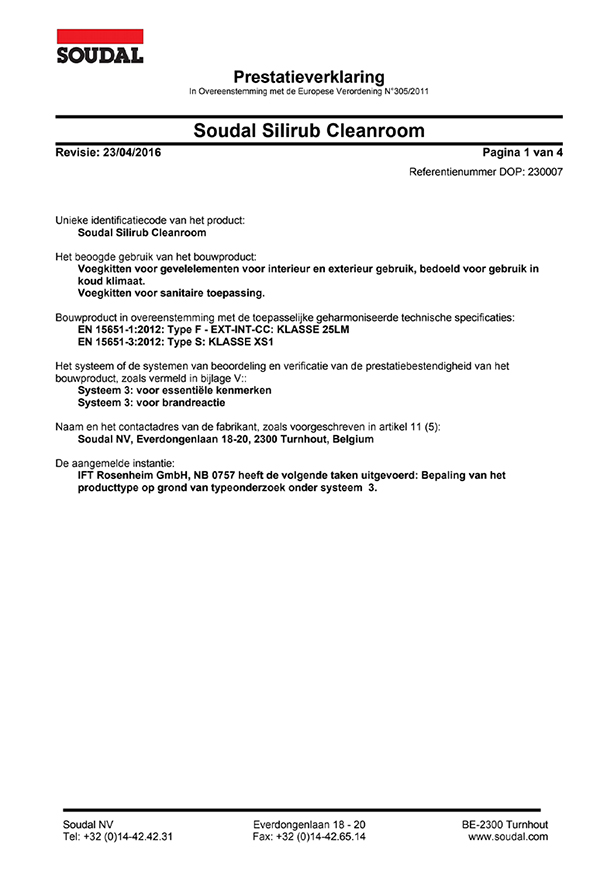

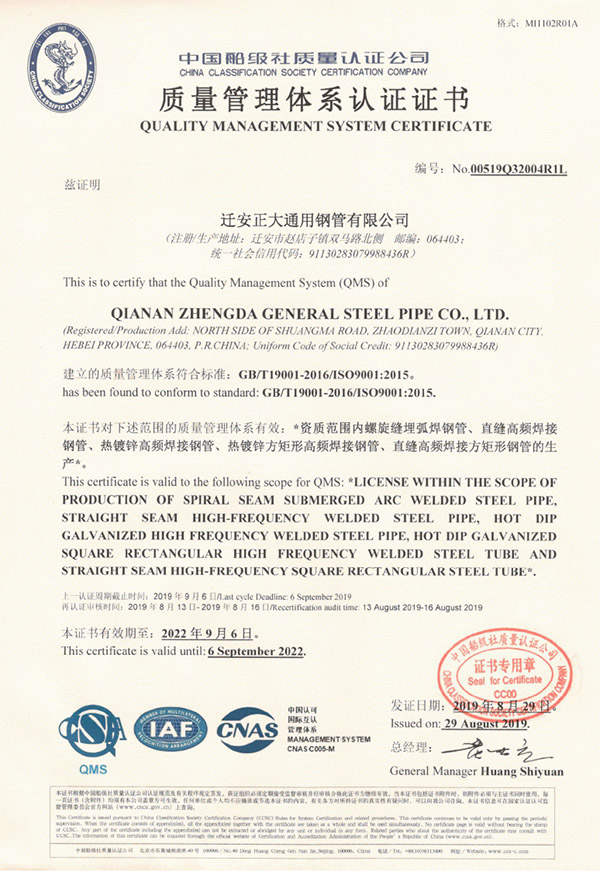

Certification authority

fAQ

1.What’s your manufacturing time?

38-45 days depends upon down payment received and shop drawing signed

2. What makes your products different from other supplier?

Strictly quality control and very competitive price as well as professional sales and installation engineering services.

3. What the quality assurance you provided and how do you control quality?

Established a procedure to check products at all stages of the manufacturing process – raw materials, in process materials, validated or tested materials, finished goods, etc

4. How to get the accurate quotation?

If you can provide the following project data, we are able to offer you with accurate quotation.

Design code/ design standard

Column position

Maximum wind speed

Seismic load

Maximum snow speed

Maximum rainfall

Cooperative company

Product detail pictures:

Related Product Guide:

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for High-Quality Steel plate curtain wall Factory – Full Glass Curtain Wall System Tempered Cladding Glass Facade Chinese Glass – Deshion , The product will supply to all over the world, such as: Philadelphia, Sevilla, Bogota, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.